The Department of Mechanical Engineering at McMaster University of Hamilton, Ontario recently began conducting biomechanical research. The projects, under the direction of Assistant Professor Greg Wohl, PhD, studies the effects of mechanical loading on bone through compression and flexure testing. The University had not conducted this type of research and, although well-equipped for mechanical testing, some new equipment was required.

The study looks at the structural and material properties of bone and includes the effects of diet, nutraceuticals, osteoporosis and aging. “We’re looking at preventative measures for bone-related disorders and/or therapies for treatment of bone-related disorders. We know that mechanical loading triggers new bone formation. However, what causes the bone formation to occur and how to maintain bone mass differ and are not as immediately apparent. So, we’re starting to look at gene expression, and what the cells does when they’re loaded,” said Wohl.

The research required a universal testing machine to perform bend and cyclical flexure tests. The tests had to be tightly monitored and controlled in order to stress specimens to pre-determined levels. The lab had an older Instron that required a new load cell, as well as likely electrical upgrades.

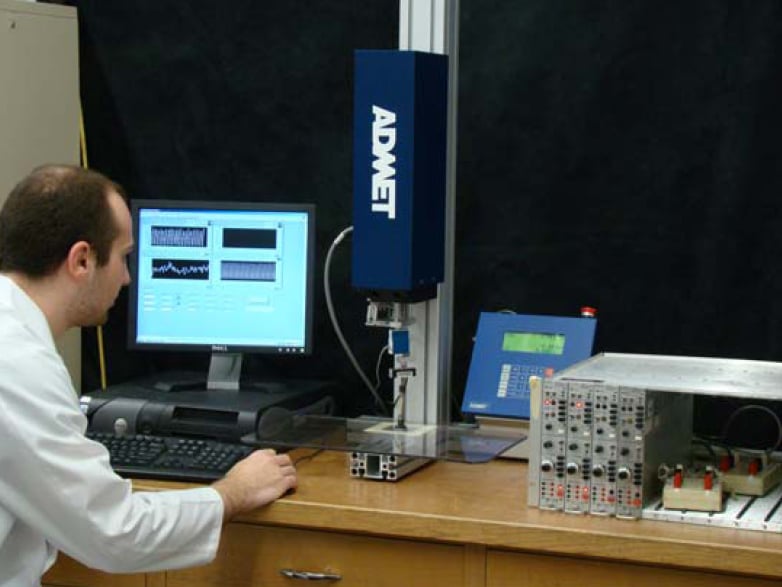

After contacting ADMET, Wohl discovered that he could purchase a new eXpert 5601 tabletop system an eP2 Digital Controller and the required load cell for approximately US$6,500 – about US$1,500 more than a new Instron load cell.

He and his graduate assistant were able to develop profiles under which they could conduct bend and cyclic flexure tests to predetermined percentages of failure and record deformation over hundreds or thousands of cycles. Wohl sees additional applications for ADMET systems. A new project will require that he conduct pull-out tests of screws for spinal reconstruction and Orthopaedic applications.