Many of us know that geckos can help save us money on car insurance. As if that wasn’t enough, MIT researchers led by Professor Jeffrey Karp are now attempting to add breakthrough medical adhesives to this unassuming lizard’s list of achievements.

Leopard Gecko (photo by Karen Shaw)

These researchers recognized the need for tough biodegradable polymer adhesives that can recover from mechanical deformations while remaining strongly attached to the underlying tissue. Although numerous tissue adhesive are currently available on the market, none of them can withstand high tensile strength or can be applied in a tape or sheet format with a programmable degradation rate that coincides with healing. An adhesive with these capabilities would be very useful as a substitute or replacement for sutures that can be difficult to manipulate during laparoscopic or microscopic procedures. This could potentially lead to shortened operating time and reduce complications such as infection.

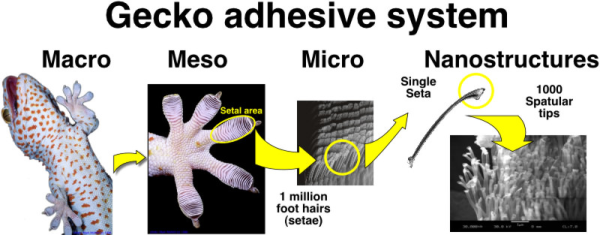

The team at MIT turned to nature for inspiration, specifically the incredible adhesive properties found in the gecko’s ability to attach to vertical surfaces while supporting their own weight. This remarkable characteristic is possible due to the fine hairs found on each gecko foot. As many as 500,000 of these hairs, or pillars, can be found on each of the gecko’s feet, each tipped with hundreds of projections known as spatulae. The pillars of spatula allow the gecko foot to conform and adhere to a variety of rough terrain.

Zoomed Detail of a Gecko Foot (courtesy of MIT)

Gecko-mimicking adhesives are currently in development. These man-made adhesives share many properties to their natural counterpart. The synthetic gecko-based adhesives are dry systems and do not require glue to achieve adhesion. The fiber-like design of the synthetic adhesives enhances its ability to interface with and conform to a variety of surfaces, improving contact with surfaces with various roughness such as tissue.

Despite these innovations, more work remains. Tissue adhesives for wet conditions require a separate set of design criteria, so dry synthetic gecko adhesives alone are insufficient for tissue adhesion. The five criteria the MIT researchers are working to meet are:

- Biocompatibility and biodegradability

- Mechanical compliance

- Incorporation of drugs, growth factors, or antibiotics

- Strong adhesion under wet conditions

- Minimal inflammatory immune response

In their efforts to perfect their synthetic gecko adhesive, the researchers needed the capability to test the tensile strength of the adhesives being developed. In 2009, ADMET celebrated its 20th year of business by awarding an eXpert 7601 Universal Testing Machine free of charge to Professor Karp’s lab.

The team at MIT has benefitted greatly from the ADMET machine. “Specifically, the eXpert 7601 has been a crucial tool for our daily work to characterize the mechanical properties of novel elastic biodegradable biomaterials that we have developed in our group. These new generation of biomaterials have been designed to mimic the behavior of the many soft tissues,” says Professor Karp. “The ADMET software has been incredibly useful given its ease of use and given that it performs automatic calculations.”

Post-doctoral student Maria Nunes Pereira adds: “The versatility and accuracy of the [ADMET] machine allows the applications of a controlled pre-load, essential to assure a conformal contact between the patch material and tissue, prior adhesion testing. The adhesive force is then determined by the maximum force observed in the load-displacement curve. We currently have in our laboratory a variety of load cells that allow us to measure forces within a broad range, according with our needs.”

To read more about the group’s gecko-based adhesive research, you can check out their published research here and here.