Check out our latest page on ASTM D3330 here

Pressure sensitive tape is used in a variety of products and applications including: electrical tape, double sided tape, masking tape, duct tape, packaging, bandages, medical devices, and much more. ASTM D3330 describes six methods used to test the adhesion strength of pressure sensitive tape. This post should help you understand the basic test procedures and choose the equipment needed to complete these tests with accuracy. For complete instructions and before determining if your products are in accordance with ASTM D3330, please refer to the official specification.

Procedures:

Test Method A – Single Coated Tapes at 180 Angle

- Adhere the specimen to the testing plate.

- Fold an end of the specimen to create a tab parallel to the plate.

- Secure the end of the plate furthest away from the tab to the moving grip.

- Secure the tab to the static grip.

- Begin peeling the tape at a 180 by moving the plate at the specified rate.

- Record the average force required for peeling.

Test Method B – Adhesion to Backing of Single Coated Tapes

- Cut and adhere a single coated specimen to the testing plate.

- Repeating steps 1-6 of test method A, adhere another specimen on top of the one on the plate and run the test.

- Repeat step 1 of test method A with a double coated specimen.

- Remove the liner and adhere polyester film in its place.

- Repeat steps 2-6 of test method A.

Test Method D – Adhesion to Liner of Double Coated and Single Coated Tapes

Double Coated Tapes

- Adhere half a piece of double coated tape to the test plate.

- Remove the lining from the half not adhered to the plate.

- Cut the tape not adhered to the plate (do not cut the lining).

- Create a tab with lining and complete the test by repeating steps 3-6 of test method A on the lining.

Single Coated Tapes

We are unaware of anyone performing test method D for single coated tapes. Moreover, no one at ADMET has been able to interpret this test method as currently written. Please leave a comment if you understand this method!

Test Method E – Adhesion of Adhesive Transfer Tapes

Face side

- Adhere the specimen to the testing plate (use a roller to eliminate air bubbles).

- Remove the liner and adhere polyester film in its place.

- Repeat steps 2-6 of test method A.

Liner side

- Adhere polyester film to the face of the tape.

- Remove the liner.

- Adhere the lining side to the testing plate.

- Repeat steps 2-6 of test method A.

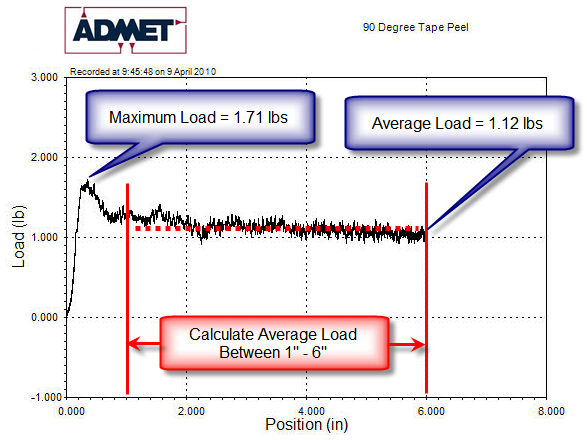

Test Method F – Single Coated Tapes at 90 Angle

- Adhere the specimen to the testing plate (use a roller to eliminate air bubbles).

- Fold an end of the specimen to create a tab.

- Fold back the tab to a 90 degree angle and connect it to the grip.

- Begin peeling the tape at a 90 angle.

- Record the average force required for peeling.

Analysis:

- Average force required for peeling.

Equipment Recommended:

- A smooth metal testing plate of the required length.

- A pair of vise grips(manual or pneumatic) to secure the plate and specimen.ADMET offers a full line of grips and fixtures for peel and adhesive testing. We are happy to custom design a fixture to meet special requirements.

- A testing machine capable of continuously pulling the tape at the required angle and force.The eXpert series of electromechanical testing machines (available in single and dual column configurations) are perfect of this type of application. Load capacity and physical space requirements should determine which system is best for your application.

- A testing controller with servo control capable of recording average load during peel.MTESTQuattro®, our most advanced testing controller, is a PC-based unit that offers a wide range of flexibility in control, data acquisition, analysis, and reporting. The eP2 Digital Controller, a standalone touch panel unit, offers a balance between performance and simplicity. Both controllers satisfy these requirements.

eXpert 7600 Single Column frame with MTESTQuattro, special 90 degree peel fixture and manual vice grips.

More Information

ADMET Adhesive Testing Solutions

ADMET Peel Testing Systems

ADMET Medical Device Testing Systems