Similar to ISO 844, ASTM D1621 is a testing standard designed to measure the compressive properties of rigid cellular plastics (i.e. foam). This post is intended to help you understand the basic test procedure and the equipment needed to perform this test with certainty. When you are ready to test your materials to this standard, please refer to the official ASTM D1621 specification.

Procedure:

- Make sure that your samples are the correct size as indicated in the specification.

- Precisely measure the area of each specimen using the method recommended in the specification.

- Center the sample in the compression platens and begin applying load at the indicated rate.

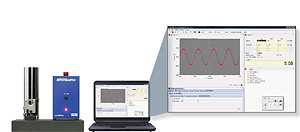

- Make sure that deflection is being recorded either automatically based on crosshead position or manually at 0.5% increments. MTESTQuattro software controller is capable of graphically displaying deflection based on crosshead position in real-time. The system can also be connected to a defectometer to provide more accurate deflection data.

- Continue to apply load until the sample yields or until the sample has been compressed to the percentage of original thickness indicated in the standard.

- Calculate compressive strength using the load amount at which ever point in step four occurs first.

Analysis:

- Compressive strain: compressive deformation % of specimen gauge length

- Compressive stress: load/specimen area

- Compressive strength: stress at yield point or indicated percentage

- Modulus of elasticity: slope of the stress/strain curve prior to yield point

MTESTQuattro Test Report

Equipment Recommended:

- A servo-controlled (constant rate of motion) compression testing machine capable of accommodating a specimen of the indicated size and apply the required load. ADMET offers a full line of single and dual column testing machines capable of performing compression tests to ASTM D1621.

eXpert 2600 Dual Column Testing Machine (left)

eXpert 7600 Single Column Testing Machine (right) - A testing controller capable of moving the crosshead at the specified rate and precisely measuring and displaying load and deflection. Both MTESTQuattro, our most advanced PC based controller, and the eP2 Digital Controller, a standalone unit, are capable of displaying a stress/strain curve in real time. MTESTQuattro will automatically perform the calculations indicated in the analysis section.

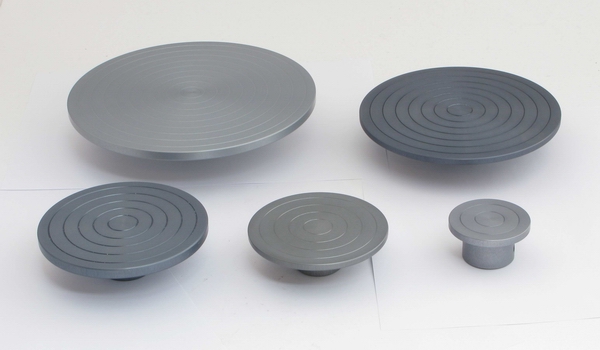

MTESTQuattro (left) eP2 Digital Controller (right) - A pair of circular or square compression platens larger than the surface area of the specimen. We offer a full line of compression platens and will custom design a fixture to hold special specimens.

- A deflectometer to more accurately measure deflection (optional). MTESTQuattro can be paired with a deflectometer to display its readings in real-time.

- A micrometer dial gauge to accurately measure specimen dimensions as indicated in the specification.