Check out our latest page on ASTM F2516 here

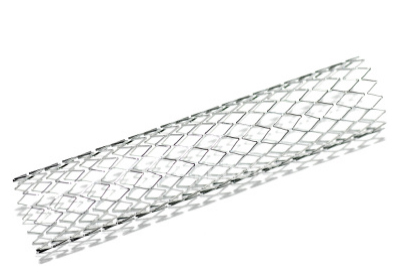

Nitinol is a metal alloy composed of titanium and nickel. nitinol is characterized by its biocompatibility, elasticity, fatigue strength, and ability to return to its original shape after deformation (shape memory). Although nitinol is used in industries ranging from robotics to clothing, it is in the medical field where the material really shines. Medical applications of nitinol include: vascular stents, eyeglasses, orthodontics, prosthetics, surgical applications, and much more.

ASTM F2516 is a testing standard designed to measure the plateau strength, residual elongation, elongation and tensile strength of nickel-titanium super elastic metals. This post is intended to help you understand the basic test procedure and equipment needed to test your nitinol products with certainty. When you are ready to test your product or material to this standard, please refer to and follow the steps in the official ASTM specification.

Procedure:

- Before moving forward with the test, please read and setup your testing setup in accordance with ASTM E8 (standard tension testing of metallic materials).

- Make sure you are testing in the temperature range indicated in the specification (about room temperature).

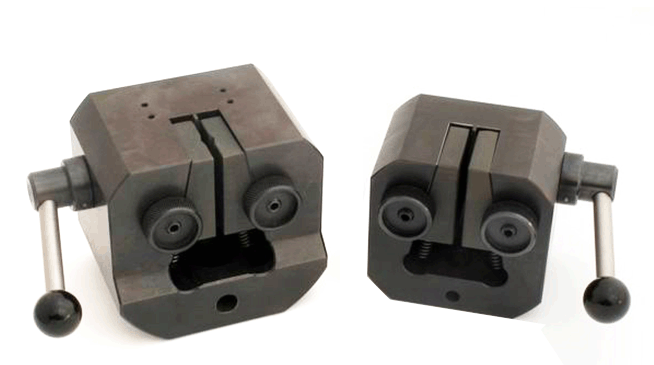

- Secure the specimen in fixtures, making sure there is no pre applied load. ASTM E8 recommends wedge grips like the ones pictured below for testing thin wire (a common form of nitinol in medical applications). If you are using an extensometer, be careful not to bend the sample.

- Depending on the diameter of your specimen, begin moving the crosshead at the specified rate.

- Continue pulling the specimen until you reach the specified strain percentage. (e.g. if the length of the sample is 12 in and the desired strain is 8%, pull until sample elongates to 12.96 in).

- Reverse the direction of the crosshead until the load reaches below the limit indicated in the specification.

- Pull the specimen again, this time until break.

Analysis:

- Upper plateau strength: stress at specified elongation % during initial loading.

- Lower plateau strength: stress at specified elongation % during unloading.

- Residual elongation: difference between strain at a specified load during loading and unloading.

- Elongation: displacement right before sample break.

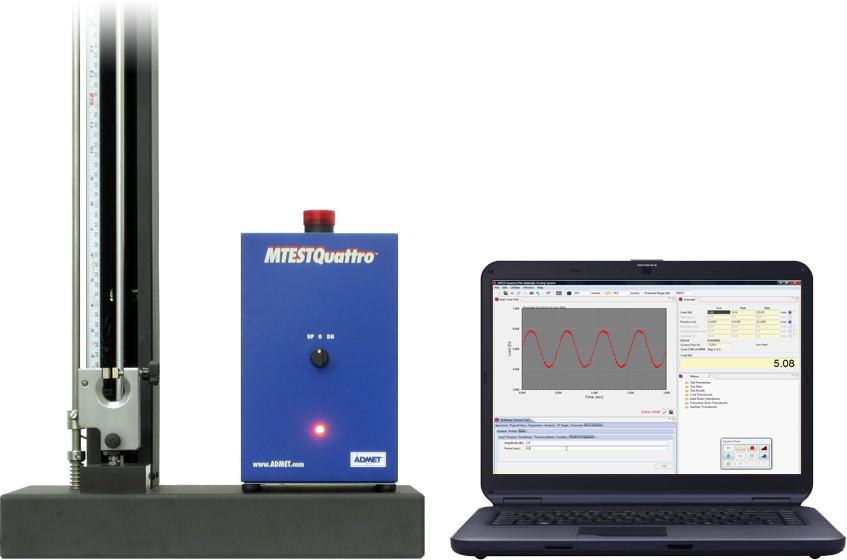

Simulated MTESTQuattro graph output

Equipment Recommended:

- A tensile testing system capable of moving the crosshead at the specified rates and apply enough load to bring the specimen to failure. The testing machine should have enough stroke to satisfy the high elongation properties of nitinol.

eXpert 7600 Single Column Frame w/ pneumatic vice grips and MTESTQuattro - A testing controller capable of moving the crosshead to the required elongation and record load and elongation for the entire test. MTESTQuattro®, our most advanced testing controller, is a PC-based unit that offers a wide range of flexibility in control, data acquisition, analysis, and reporting satisfies these requirements.

- A pair of grips to securely hold your sample. ASTM E8 recommends wedge grips for thin metallic wire sample. We offer a full line of grips and will custom design grips to hold any type of material.

- If needed, ADMET offers a full line of long travel and clip on extensometers to help you more accurately measure elongation.