Find useful definitions of many terms related to materials testing below. Have questions about a term or a suggestion for one that isn’t on the list? Feel free to contact us!

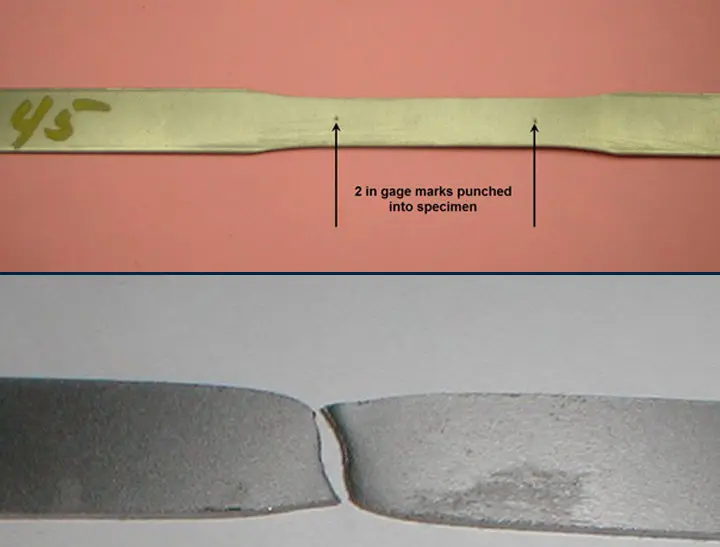

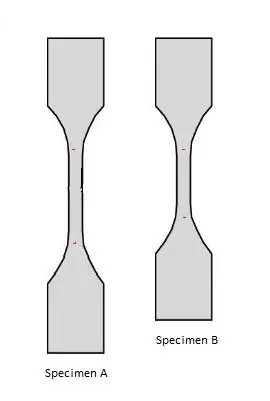

Ductility

Governed by ASTM E8, ductility is the ability of a material to deform before fracture. For a more in-depth definition, explore our ductility page.

Elongation at Break

One measure of ductility governed by ASTM E8, elongation at break is obtained by pulling a specimen in tension until fracture. Read our elongation at break page to learn more about the process and how elongation is calculated.

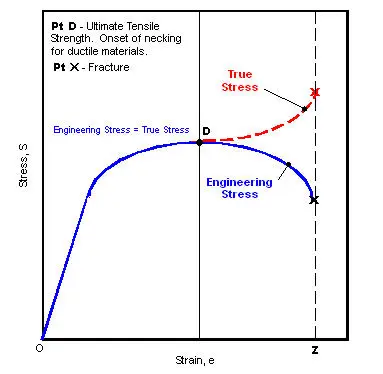

Engineering Stress / True Stress

Before rupture or break, ductile materials undergo plastic deformation. Engineering Stress and True Stress can tell us a lot about the forces before and after necking. Engineering Stress (ES) is the applied uniaxial tensile or compressive force at time i divided by the original cross-sectional area of the specimen. In contrast, True Stress (TS) is equivalent to the applied uniaxial tensile or compressive force at time i divided by the cross-sectional area of the specimen at time i.

Take a look at our engineering stress / true stress page to learn more about these measures and how they are calculated.

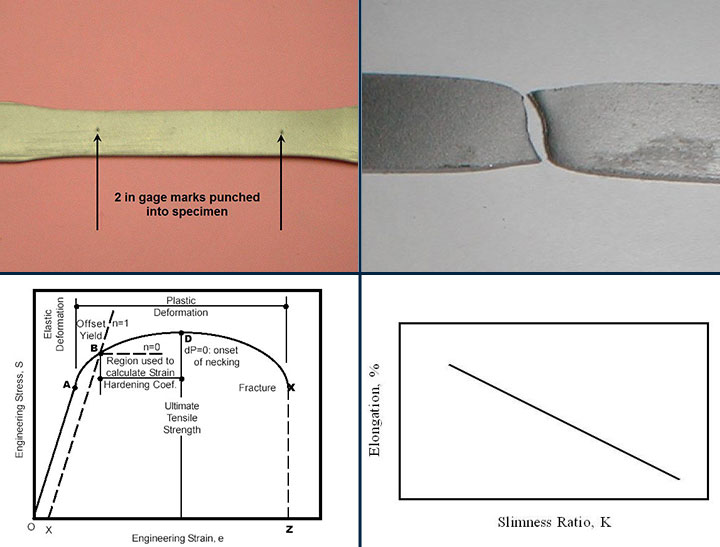

Gauge Length

The Gauge Length is the original length of the portion of the specimen over which strain, elongation, or the change of length is determined. Testing standards often specify a gauge length selection based on the material being tested. For further information on the effect of different gauge lengths on test results, click here.

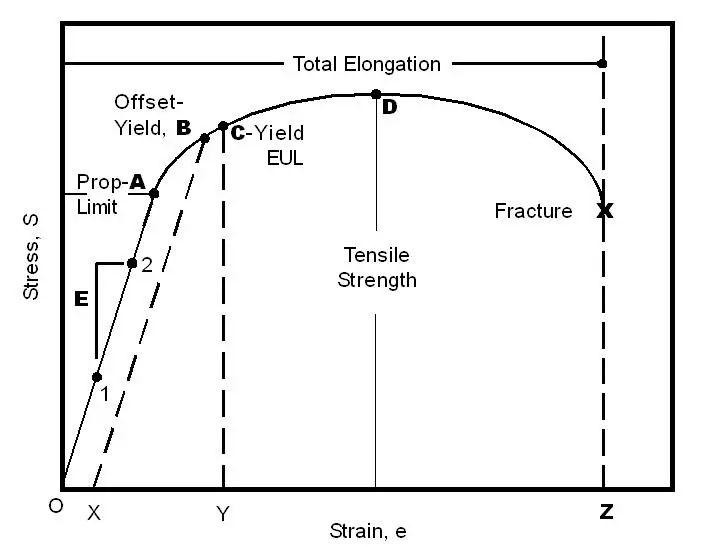

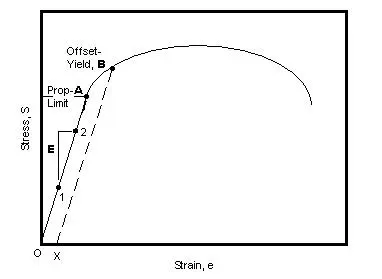

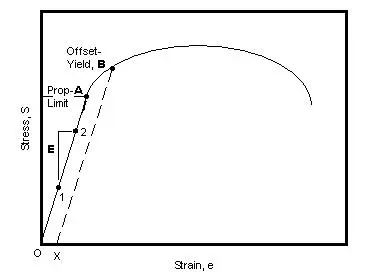

Offset Yield

The offset yield strength is the point where a line drawn parallel to the modulus line intersects the stress-strain curve. Explore our offset yield page to learn more about how this metric is measured.

Proportional Limit / Elastic Limit

The proportional limit of an elastoplastic material is the point at which it can no longer return to its original length when all forces are removed. To learn more about this metric, explore our proportional limit / elastic limit definition page.

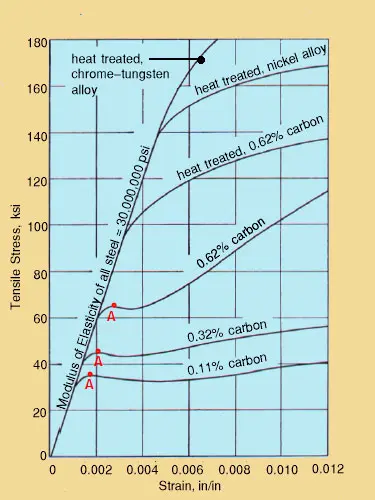

Stress Strain Curve

A stress strain curve relates the forces on a member to the deflections imposed by the forces. It is typically depicted with an XY graph like the one above. To learn more about this curve and how it is measured and graphed, take a look at our stress strain curve definition page.

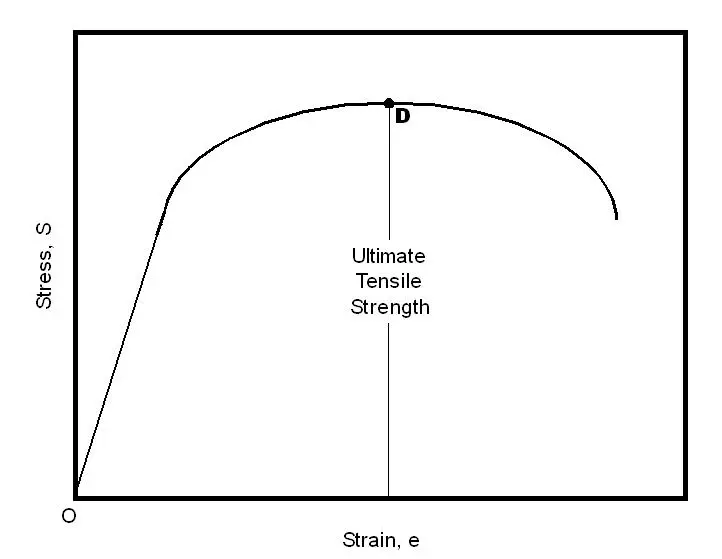

Tensile Strength

The maximum stress applied in tension to a material before rupture is defined as the Ultimate Tensile Strength (UTS). ASTM E8 governs the determination of Ultimate Tensile Strength for Metals and ASTM D638 governs the determination of Ultimate Tensile Strength for Plastics. Explore our tensile strength page to learn more.

Yield Point

The Yield Point is the stress at which there is an appreciable increase in strain with no increase in stress — with the limitation that if straining continues the stress will again increase. ASTM E8 governs the determination of Yield Point for Metals. To learn more, review our yield point definition page.

Yield Strength

The Yield Strength, used for materials without a yield point, is the amount of stress that will induce a specified permanent set, usually 0.2%. Yield strength is governed by ASTM E8 for metals ASTM D638 for plastics. Review our yield strength page to learn more about this metric.