The Right Accessories for Your Testing Needs

ADMET mechanical test grips and fixtures come in a range of designs and materials, tailored to accommodate different types of samples and testing requirements. Whether dealing with metals, polymers, composites, or other materials, we offer the right choice of grips, fixtures, and accessories to obtain valid and reliable data. ADMET accessories, compatible with both ADMET machines and other makes and models, handle various forces and environmental conditions without compromising the integrity of the test.

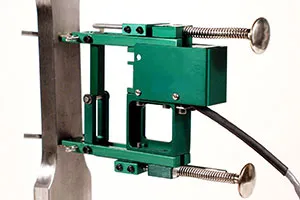

Grips & Fixtures

ADMET test fixtures and grips can be used with virtually any manufacturer’s test frames. All we ask are details of your application to make sure our products will provide you what you are looking for. If you are unsure of the performance of a grip, send your samples in so we can test them with our various grip solutions!

Testing Accessories

Extensometers, transducers, and load cells are wired and chipped to be used with ADMET electronics only. Our smartducer chip technology allows users to switch between transducers without needing to recalibrate the transducer.

Environmental chambers are available to provide heating or cooling during testing. Test sample preparation tools are used for cutting specimens to the exact dimensions described in an ASTM/ISO standard. Specimen dies can be used with a toggle press or a mallet handle. We offer specimen dies as described by ASTM and ISO standards and also per customer-specific dimensions.

If you need help choosing accessories, contact one of our engineers

About Our Products

Mount your Samples Safely and Securely

ADMET offers a full line of grips and fixtures for materials and product testing. The grips and fixtures that we sell support our entire line of new universal testing machines. They can also be used with virtually any manufacturer’s test frames and with ADMET retrofitted equipment. There are hundreds of grips available. If you don’t see the grips or fixtures you need then please ask us.

Get the Accuracy You Need

Extensometers are used to accurately measure specimen extension during tensile testing. Specifications for extensometers include gauge length, which is the distance between the knife edges at the start of the test and percent travel or elongation during test.

Deflectometers are used with samples undergoing compressive loading to measure the most accurate deflection data. A compressometer-extensometer assembly is for measuring Poisson’s ratio and Modulus of Elasticity.

Test in the Right Conditions

Environmental chambers and baths are used to heat or (if supplied) cool samples while testing. Typically used on dual column machines, where the chamber can be pushed to the back of the machine when not in use. All chambers are supplied with temperature controllers. Liquid nitrogen or CO2 is used to cool samples.

Use the Right Amount of Force Sensitivity

ADMET load cells range from very low forces to higher end forces to test materials of various capacities. Each load cell can be used down to 1% capacity to meet the requirements of ASTM E4. We offer different types of load cells to be used in various test types such as tension, compression, fatigue, and torsion. ADMET load cells ship to your facility wired and chipped and include calibration documentation.

Prepare your Samples to Meet your Needs

Test sample preparation tools are used for cutting specimens to the exact dimensions described in an ASTM standard. Specimen cutting dies can be used with a toggle press or a mallet handle. We offer dies for almost every ASTM standard. Some of the popular ASTM standards that require cutting dies include: ASTM D412, D624, D638, and D882. Please specify the ASTM and the specimen type if you’d like to order specimen cutting dies.