ADMET offers calibration services to customers who operate both ADMET equipment and systems made by other manufacturers. We serve all major global markets and offer a wide range of fatigue options.

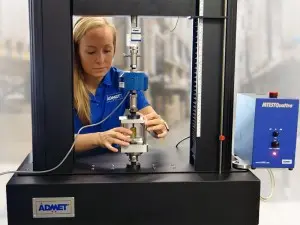

An ADMET Calibration engineer works on a system

Over time, the accuracy of all electronic components like load and displacement transducers can change due to age or misuse. Although ADMET utilizes the highest quality equipment available, regular calibration ensures that these components perform as required so the results generated can be trusted with confidence.

Organizations like ASTM and ISO create standards and procedures which dictate how the calibration for a specific piece of equipment should be performed. In order to provide a traceable calibration, calibrators must first be ISO/IEC 17025:2017 accredited. ISO/IEC 17025:2017 accreditation specifies the general requirements for competency to carry out tests and/or calibrations and confirms the traceability of equipment back to the relevant governing authorities.

Download our Calibration Services brochure here.

ADMET’s Calibration Scope

Below is a partial list of internationally recognized procedures ADMET follows to calibrate testing equipment. If you don’t see what you need on this list, please contact ADMET to discuss your needs.

- ASTM E4 – Tension Force Calibration

- ASTM E4 – Compression Force Calibration

- ASTM E2624 – Torque Calibration

- ASTM E2309 – Crosshead Displacement Calibration

- ASTM E2658 – Crosshead Speed Calibration

- ASTM E1012 – Specimen Alignment Verification

- ASTM E2309/E2658 – Strain Rate Calibration

- ASTM E2309/E4 – Load Rate Calibration

- ASTM E83/ISO 9513 – Extensometer Calibration

- ASTM E467/NASM 1312 – Dynamic Force Calibration

Calibrating an eXpert 2600 dual column testing machine

Need to discuss calibration options with an expert?

Digital Calibration Stand

Levels of Calibration

Different levels of calibration are available and each has their own implications as far as traceability.

Factory Calibration

All ADMET equipment receives a baseline calibration used to verify machine functionality before shipment.

ASTM Calibration

Service is performed according to the detailed procedures as laid out by ASTM for the applicable calibrations. Note that some calibrations require this to be performed onsite where the machine will be operated.

ISO/IEC 17025:2017 Accredited Calibration

This accreditation verifies the competency of the calibrator and the traceability of equipment back to the National Institute of Standards and Technologies (NIST). If the end user is basing a critical decision on measurement results or publishing data, an ISO/IEC 17025:2017 calibration is recommended.

ADMET Calibration Equipment

Equipment for Dimensional Calibration

ADMET utilizes several devices to conduct dimensional calibration including a high precision micrometer head for the smallest ranges and lowest uncertainty for ASTM E83. Linear encoders and digital indicators are used for ASTM E2309 and E2658.

Equipment for Calibrating Mass, Force, and Weighing Devices

ADMET employs dead weights for low ranges from 0.001 lbs to 10 lbs for both compression and tension. Load cells are typically used to perform calibrations above 10 lbs for ASTM E4. These load cells have 3-run NIST traceable ASTM E74 calibrations.

Equipment for Time and Frequency Calibrations

Crosshead speed calibration per ASTM E2658 are measured directly with ADMET’s GaugeBuster 2 Calibration unit.

Some of ADMET’s calibration equipment

Supported Brands

We calibrate systems made by a range of manufacturers including ADMET, MTS, Shimadzu, Tinius Olsen, retrofitted Instron®, and SATEC®.