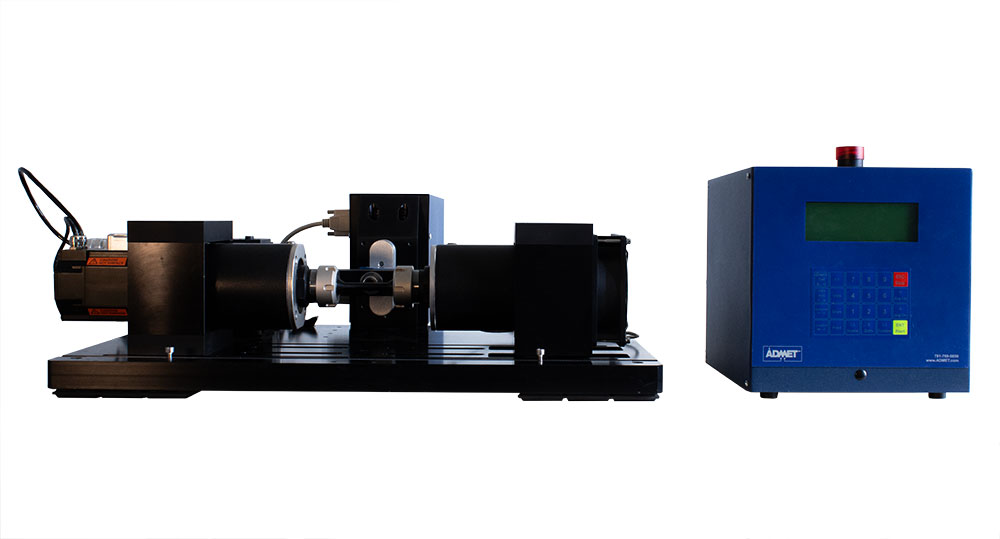

A highly respected research University approached ADMET with an interesting problem. They needed a very cost-effective way to test the fatigue life of polymer lattice structures to ensure that certain 3D printed knee replacement prostheses would hold up over time.

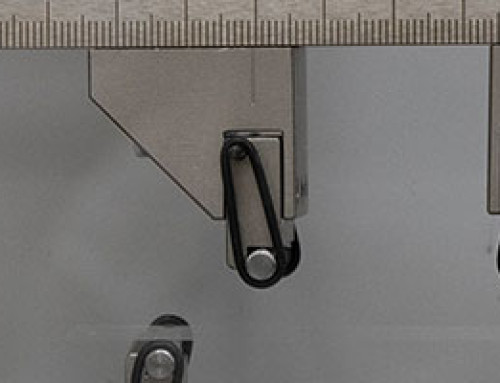

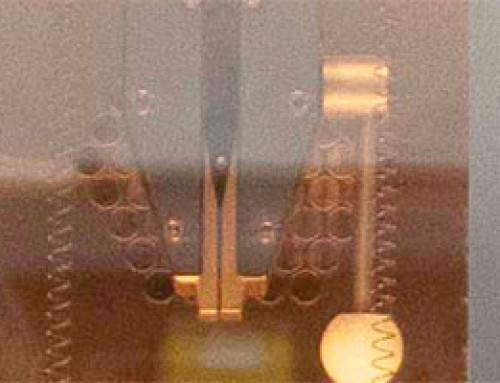

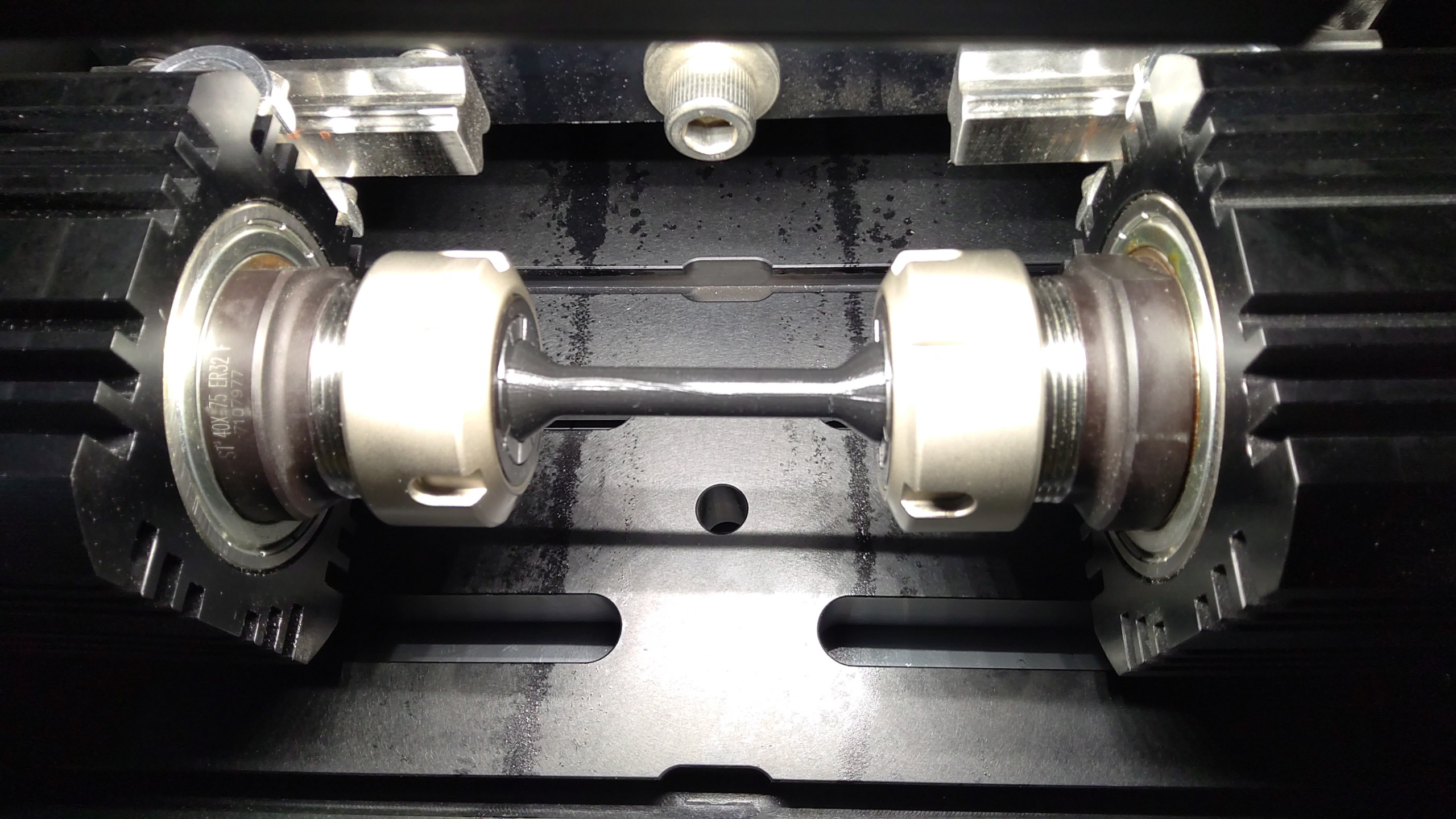

A polymer lattice sample held in rotating beam fatigue fixtures

Since budget was limited and fatigue testing was critical to supplement existing static loading data, Rotating Beam Fatigue testing was a strong consideration as opposed to more expensive axial fatigue test systems.

By design, Rotating Bending Fatigue Tests are typically more suited to metals and other high strength materials. The stresses applied to the customer’s materials for this testing were only expected to be on the order of 10MPa to 140MPa (1,450psi to 20,300psi), as the polymer lattices used in knee replacements may be designed for up to 50% porosity to allow for the flow of cells and other biomaterials.

To help the customer solve their testing challenge, ADMET provided a unique Rotating Beam Fatigue Test System that utilized a more compliant loading mechanism. This mechanism helped to optimize the low capacity testing and reduce load peaks & valleys seen with the unbalanced nature of 3D printed polymer specimens that might not spin true on the test system.

Are you performing fatigue testing on polymers?

We’ll help you find the right test system for your application