Fatigue Testing Machines | For Dynamic Testing

Fatigue testing allows manufacturers and researchers to get a critical understanding of how a material or component will perform in real-world loading scenarios over the course of time. ADMET offers a wide range of fatigue testing systems to suit your testing requirements. Higher capacities for each system can be accommodated based on customer needs. Speak with one of our sales engineers to learn more.

Electromechanical Fatigue Testing Systems

The eXpert 5900 series tabletop dynamic testing machine is a compact, quiet, and clean electrodynamic testing system for determining the durability of materials and components in tension, compression, or flexure.

eXpert 5900 series machines perform fatigue testing up to 15Hz in frequency and provide up to 14kN in load capacity. Custom designs are also available. The 5900 series actuators are a unique electromechanical design that features a direct drive bearingless motor, flooded bearing stack, and ball screw with continuous lubrication. This design greatly extends the life of the actuator and is ideal for performing cyclic tests at small or large amplitudes over millions of cycles. This makes Low Cycle Fatigue (LCF) and High Cycle Fatigue (HCF) tests a possibility up to the 15Hz range.

Torsion Fatigue Testing Systems

eXpert 9900 series Table Top Torsion Fatigue Testing Machines are available in vertical or horizontal orientations. Horizontal systems feature a fixed spindle with sliding tail stock while vertical systems employ a sliding drive spindle. Maximum torsional stiffness and minimal axial friction are achieved with a roller slide frame design. A reaction torque transducer can be mounted to the tail stock or a rotary torque transducer can be mounted to the drive spindle to accommodate a wide range of applications.

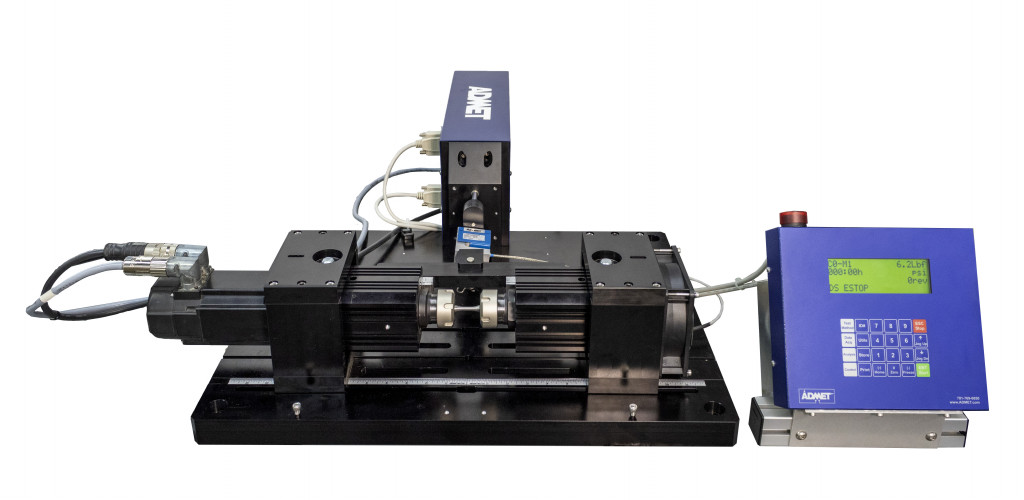

Biaxial Fatigue Testing Systems

The eXpert 8900 Axial-Torsion Fatigue Testing Systems is ideal for performing fatigue testing on specimens that require both a torsional and axial load. The system has a maximum dynamic force capacity of 17.5 kN (3,934 lbf) and maximum dynamic torque of 80 Nm (708 lbf-in). The eXpert 8900 has dynamic capabilities up to 20 Hz. ADMET engineers can customize the eXpert 8900 to meet your specific testing requirements. Click here to learn more about the eXpert 8900.

Servohydraulic Fatigue Testing Systems

Standard eXpert 1900 Series dynamic test systems are available in capacities from 10kN (2,250 lbf) to 250kN (56,000 lbf). Every eXpert 1900 Series tester is engineered to meet the force-stroke-frequency requirements of each application. Depending on the size of the hydraulic power supply (HPU), the 1900 Series HPU is either integral to the frame or free standing.

- eXpert 5950 – ISO 14801 in a heated fluid bath

- eXpert 5955 – ASTM F2077 (Intervertebral Body Fusion Devices)

- eXpert 5955 – For ASTM F2077 with ADMET’s MTESTQuattro controller software

- eXpert 9300 Rotating Beam Fatigue – Safety cover off

- eXpert 9300 Rotating Beam Fatigue Machine – Sample failure

- 5951 Electrodynamic Testing Machine with Manual Vise Grips and Adjustable Crosshead

- eXpert 5955 – Fatigue testing in an F-280DT Environmental Chamber

- eXpert 8900 – Biaxial Fatigue Testing Machine

- eXpert 5952 – Electrodynamic Testing Machine equipped with Compression Platens

- eXpert 5950F – Foam Fatigue Tester

- eXpert 1900 UTM – Hydraulic Fatigue Tester

- eXpert 1900 with Hydraulic Grips

- eXpert 9900 – Vertical Torsion Tester

Controllers for Fatigue Testing Systems

Users of ADMET’s dynamic fatigue testing systems have a choice of two controllers: the MTESTQuattro high-speed closed-loop controller, or the DC1X Dynamic Fatigue Controller.

MTESTQuattro can be programmed to generate sine, square and triangular waveforms. Users can manually adjust control gains and endpoint values on the fly or activate amplitude control so that the controller automatically adjusts the endpoint values to ensure that the dynamic fatigue testing systems desired targets are met.

The DC1x controller is an ideal, cost-effective solution for basic cyclic fatigue testing applications. It is compatible with all ADMET servo-hydraulic and electro-mechanical dynamic test systems and can also be retrofitted to a wide variety of testing systems from other providers. It provides basic sine, square, and triangle waveforms. Amplitude control is a standard compensation program that tracks the feedback signal and automatically adjusts amplitude and setpoint control values until the desired peak and valley levels are achieved. This occurs continuously, ensuring all levels are within tolerance. It is ideal for cyclic tests under load control where test systems or specimen characteristics vary over time. During test, users can view peak/valley and the number of cycles completed.

Featured Configurations

Rotating Beam Fatigue Torsion Tester

ADMET’s Rotating Beam Fatigue Tester applies force via a pure bending moment and spins the sample at up to 6000 RPM. It is ideal for evaluating fatigue life and creating SN curves.

eXpert 1900 for High Force Fatigue Testing

ADMET offers the eXpert 1900 servohydraulic fatigue tester for customers who require high-frequency fatigue testing on plastic, metal, and other rigid components.

eXpert 4900 for Additive Manufacturing Research

The eXpert 4900 MicroTesters are commonly used by academic and research institutions studying the effects that the additive manufacturing process has on metallic materials. These systems allow researchers to test very small test specimens while providing the ability to visualize and quantify any of the imperfections/voids in the specimen under a microscope. Once the microstructure is better characterized, more meaningful conclusions can be drawn from fatigue testing results.

eXpert 9900 for Torsion Fatigue Testing

ADMET’s 9900 torsion fatigue tester is a highly customizable testing system available in a range of configurations based on customer requirements.

eXpert 5955 – ASTM F2077 Intervertebral Body Fusion Device Testing

The eXpert 5900 electrodynamic testing machine equipped with MTESTQuattro controller & software was configured to run ASTM F2077 Intervertebral Body Fusion Device Testing.