Engineered Solutions | Designed to Order

ADMET has the expertise to design, build, deliver, and implement custom mechanical test equipment from small table top electromechanical systems to high capacity hydraulic test frames. Our team will work with you from the initial contact to ensure that the system is designed to meet your exact requirements and will be reliable and easy to use. Custom projects are based on our proven MTESTQuattro controller and software in use on test frames around the world. ADMET’s engineering group is structured to handle unique and demanding projects and we look forward to working with you.

Below are some examples of engineered solutions we’ve built for customers in the past.

- Material Wear Testing Machine for Airline Seat Cushions

- Material Wear Testing Machine for Airline Seat Cushions Demo

- eXpert 5952 Dual Actuator System arranged for testing automotive springs

- eXpert 5952 Dual Actuator System – Automotive Spring Demonstration

- eXpert 9600 Vertical Torsion Tester – Tool/Screw Testing application

- eXpert 9600 Vertical Torsion Tester – Tool Testing Demonstration

- eXpert 8900 – Axial Torsion Fatigue Testing System Demonstration

- eXpert 2600 with Digital Image Correlation System (DIC) and Environmental Chamber

- eXpert 8900 – Axial Torsion Fatigue Testing Machine

- eXpert 2657 with Safety Cage

- Custom large pipe testing system

- Custom Solution: Cement Seal Testing Machine for ASTM D5835

- Inverted hydraulic machine for testing aerospace landing gear

- Inverted 600kN fatigue system for testing large composite components

- Customized eXpert 5600 for Mattress Testing

- Environmental Chamber glassview port for use with Video Extensometry

- Inverted 600kN compression system for testing medical devices

- eXpert 5952 5kN system with customer fixture and blackout chamber for testing solar panels

- 25,000 in-lb torsion system for testing high performance automotive springs

- eXpert 5603H Mattress Tester with adjustable actuator position

- ASTM D6128 Shear Test of Bulk Solids on ADMET Biaxial Testing Machine

Our engineers will work with you to develop a customized testing solution that fits your exact requirements. Force capacity, stroke, machine size, and many other characteristics can be tailored to suit your specifications. Please contact us today by filling out our sales contact form or call us at (800) 667-3220.

Featured Configurations

eXpert 5952 Solar Panel Bend Testing System

This eXpert 5900 system has been specially configured to be the ideal instrument to perform bend testing (static and dynamic) on solar panels. The system includes a specialized bend fixture for solar cells and a camera to capture solar cell crack propagation triggered by ADMET MTESTQuattro controller and software.

Click here for more information and a video.

Horizontal Pipe

Tensile Tester

This large custom system is perfect for customers who need to test entire pipe sections and their fusion welds. The system features a dual stage hydraulic power unit to allow faster speeds when jogging the actuator under no load conditions and a hand-held tethered controller to jog actuator from any location around the machine.

Click here for more information.

eXpert 8600 for Solid Ice Specimen Testing

The eXpert 8600 configuration for testing solid ice specimens was amongst the slowest moving 8600 series machines built with speeds down to 0.8 degrees per minute. The testing system was equipped with an environmental chamber and a custom-designed fixture for ice specimens to allow very precise angular movements. In addition, backlash kits with adjustable spring loaded fixtures were included to preload the axial actuator in compressive and torsion CW and CCW directions.

Click here for more information.

Custom Large H-Frame Furniture Tester

This customized test frame has a repositionable actuator that moves independent of the crosshead, giving users maximum flexibility in test preparation and specimen dimension. Static testing can be performed with ADMET’s eXpert 5600 series actuators, while faster and more dynamic tests can be handled by eXpert 5900 series actuators.

Click here for more information and a video.

eXpert 5600 Bulk Solid Shear Testing System

Adapted from “ASTM D6128 – Standard Test Method for Shear Testing of Bulk Solids Using the Jenike Shear Tester”, the Bulk Solid Shear Tester is a bi-axial system with a fixture designed per ASTM D6128 and a vertical actuator that applies consolidation force to eliminate the need for user to apply a heavy dead weight stack. The ASTM D6128 testing system is capable of both cohesive shear and wall friction tests by changing out test coupons.

Click here for more information.

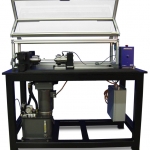

“Squirmin’ Herman” Testing System for Seat Cushions

ADMET wear testing machines come with a dynamic actuator and the fixturing required to run the test of your choice. This featured configuration shows the dynamic foam testing system with the Squirmin’ Herman fixture, designed per the standard and is used to investigate the effect of aircraft passenger wear on seat upholstery fabrics and fire blocking layers.. The dynamic movement can be controlled by both position and load.

Click here for more information and a video.

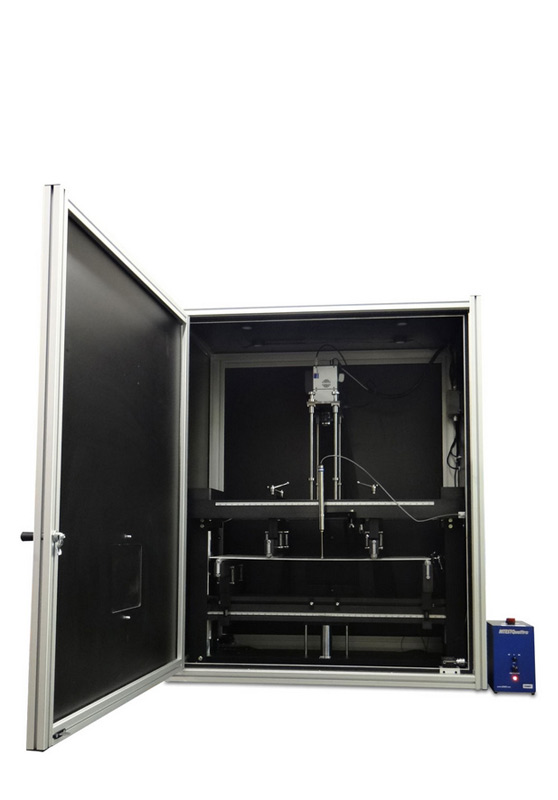

eXpert 2600 Video Extensometer and Tripod Slide System

eXpert 2600 frame equipped with a 2D DIC system on a tripod slide system to give the customer the ability to quickly and easily change from one test to the next where radically different material specimens and elongations are tested. The rail system allows easy slide from about 1ft working distance to specimen to 8ft-12ft. The system is equipped with an environmental chamber to allow testing at various temperatures.

Click here for more information.

eXpert 5600 Small Specimen Fatigue Testing

eXpert 5600 configured for very slow tensile tests on order of 10^-5 mm/mm/sec strain rate on specimens that are about 2mm in gauge length features a unique grip design with an alignment fixture to connect to the two opposing grips to ensure perfect alignment. It also incorporates alignment fingers to ensure that the specimen would be perfectly vertical in the plane of the grip faces.

Click here for more information.

eXpert 2650 Series Wide Testing System

eXpert 2650 Series Wide UTMs are a great option for customers who require a large testing space as well as precise load and position measurements. The column to column dimension can be widened by 12” increments. Large t-slot or tapped hole base plates are often supplied with this configuration to allow the user the space and freedom to test large and oddly shaped test specimens and final products.

Click here for more information and a video.

Servohydraulic Power Unit for Concrete Fatigue Testing

ADMET engineered a Servohydraulic Power Unit with MTESTQuattro to perform 2Hz force amplitude based fatigue tests on 4 by 8” cylinders. Parts supplied for this project included a 3,500psi pumping system to generate up to 175,000lbf of force and a linear encoder with 3” stroke for position measurement on the existing CM-4000 testing frame.

Click here for more information on our retrofit services.