Check out our latest page on ASTM D1708 here

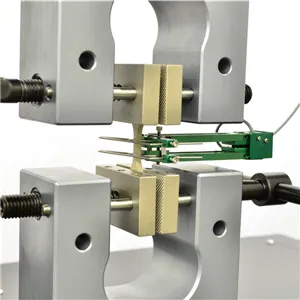

Grips and extensometer for ASTM D1708 microtensile testing

Summary:

Historically, test method ASTM D1708 has been used to measure the tensile and elongation properties of plastics that have little amount of material available. There are also many other ASTM test methods for specific materials (FEP, ETFE, PTFE) that reference the same test method a list of which is referenced below. A change has been made to the ASTM D1708 tensile specimen shape so that it now is the same as the shape found in ISO 12086-2. ASTM D1708 is no longer the preferred plastic microtensile method as ASTM recommends the much more common ASTM D638 tensile test using the very small type V specimen shape. If interested, another ADMET page discusses ASTM D638 here.

The convenient feature of D1708 is that the specimen shape is such that an extensometer is not required to perform the test. Rather, the universal testing machine’s built in jaw separation position is sufficient to measure elongation. It becomes critical however that you have a very accurate initial jaw separation which happens to be less than an inch.

Equipment Required:

- Universal Testing Machine (UTM) of the constant-rate-of-crosshead-movement variety. I’m not aware of any manufacturer that makes anything but this type anymore. However, the UTM should be servo-controlled to maintain the set speed throughout the test.

- Load Cell accurate to at least 1% of the reading. Also, the breaking strength of the material should be between 1/100th and the full capacity of the load cell. For example, a 100 lbf load cell should be used to measure from 1 – 100 lbf.

- Tensile Grips of the “vise” or “side action” variety so as not to interfere with the elongation measurement. Serrated, plain, and rubber coated jaw faces can be used. Pneumatic grips of the “side action” type can also be used. Self-tightening grips such as eccentric roller and wedge styles are not good for this test. Eccentric roller grips are hard to set the jaw separation properly and wedge grips have the same problem but can also add an undesirable compressive load on the sample. Systems that adjust grip separation automatically to accommodate a compressive load then adjust the gauge length. It’s not tricky as it sounds if you use a simple pair of manual tensile vise grips.

The cost for a system that meets the accuracy requirements of the specification and include all the items above generally start at around $ 8,000 USD. Depending on vendor and options chosen, typical 1kN – 50 kN systems range in price from $8,000 – $ 40,000 USD. The major cost driver with these systems is the maximum force capacity of the system. 1 kN & 5 kN single column systems are sufficient for many materials when testing to a microtensile method and are the most cost effective. Larger capacity 10, 25, 50, 100 kN and higher dual column systems are also available that can perform this test as well and performing other high capacity tests.

Other Microtensile Test Methods:

- ASTM D2166 Section 11.4 – Tensile Properties of FEP Fluorocarbon Molding and Extrusion Materials

- ASTM D3159 Section 11.4 – Tensile Properties of Modified ETFE-Fluoropolymer Molding and Extrusion Materials

- ASTM D4745 Section 12.4 – Tensile Properies of Filled Compounds of Polytetrafluoroethylene (PTFE) Molding and Extrusion Materials

- ASTM D4894 Section 10.7 – Tensile Properties of Polytetrafluoroethylene (PTFE) Granular Molding and Ram Extrusion Materials

- ASTM D4895 Section 10.7 – Tensile Properties of Polytetrafluoroethylene (PTFE) Resin Produced From Dispersion