Introduction

Manufacturers of metals, including producers of raw material or finished metal products, need to pass compliance standards before shipping their product. Tensile testing is imperative for ensuring a safe, high quality material and avoiding the major liabilities associated with providing non-compliant products. These actions will keep the end consumer satisfied and dramatically reduce the chance of failure in the field. Below, we will discuss ASTM E8, an international standard for determining the tensile strength of metals.

ASTM E8: Specification for Measuring Tensile Strength of Metals

The ASTM E8 test provides data on the strength and ductility of metals under uniaxial tensile forces. The tensile strength of a metal is essentially its ability to withstand tensile loads without failure. Ductility, on the other hand, measures a material’s ability to deform under tensile stresses. This is an important factor in metal forming processes since brittle metals are more likely to rupture. Metals that break or crack when stressed cannot be transformed during hammering, rolling, or drawing.

Technicians who conduct tensile testing of metals measure a number of mechanical properties to determine the material’s quality. The figure below is a stress-strain curve which provides a graphical representation of these mechanical properties. Some of the critical measurements include: peak stress or ultimate tensile strength (Point D), rupture or fracture point (Z), offset yield strength (B), and percent elongation at break.

Why is Tensile Testing so Important?

Metal fabricators are challenged to provide materials to the automotive, aerospace, and construction sectors that have the right strength and ductility. These sectors follow stringent safety regulations. The performance of their materials are a matter of life or death – cars and airplanes cannot fail, and buildings must stay standing. For instance, according to AP news reports, the recent disaster in a factory in Bangladesh – more than 1100 workers perished when the building collapsed — was in part caused by loading the building beyond its designed structural capacity. Properly designed and tested structural additions may have averted the catastrophe.

A subset of the metal industry worthy of special mention is the research and development of novel metal alloys. Metal alloys are designed to provide material properties tailored to specific applications and uses. Load bearing steel beams are fabricated with high strength materials, but steel that is used for framing in walls needs to have a certain amount of ductility to allow it to be formed into shape and to enable fasteners, such as drywall screws, to work — if the steel is too brittle, it will crack. Tensile testing is the most common method for determining these material properties. Alloys are tested for strength and ductility at all phases of the product life-cycle, from R&D to inspection of incoming materials to quality checks on finished goods.

Another good example of tailored material properties for specific applications is the automobile, in which the design of the frame in the engine compartment utilizes different materials than the doors and pillars that hold the drivers and passengers. The right combination of ductility and strength in the right places improves safety and crash management through Energy absorption.

The automotive and aerospace fields also invest heavily in research and production using lightweight materials, which reduce the overall fuel required to move a machine, but must still meet the strength requirements of the application. Having fast, accurate feedback on the strength of the metals used is critical to all of these applications — how can ADMET help?

ADMET Solutions for Tensile Testing

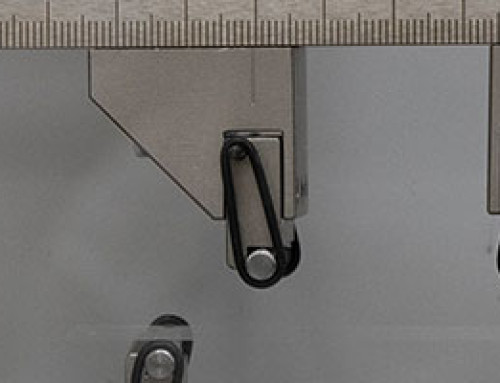

For meeting the challenges of tensile testing, ADMET provides the eXpert 2600 Series Dual Column Universal Testing Machines equipped with wedge grips, extensometers, and the PC-based MTESTQuattro(R) Materials Testing Software and Controller. eXpert 2600 Series Testing Systems are offered in capacities from 5kN to 250kN and are well suited for determining the tensile properties of metals.

Materials testing systems are a must for determining the strength and ductility of metal and metal alloys. To learn more about ADMET’s eXpert 2600 Series Universal Testing Systems or other metal testing solutions, please contact us!