eXpert 2600 | Powerful and Versatile

The eXpert 2600 series universal testing machines are available in table top or floor standing standard configurations from 2kN to 600kN. These systems tackle the toughest tests with their superior axial alignment, stiffness, and crosshead guidance. A simple design allows for lower cost, faster delivery, and years of maintenance free operation. All eXpert systems are capable of performing reliable and repeatable tension, compression, peel, and flexure tests. ADMET offers a full line of grips, fixtures, load cells, extensometers as well as heating and cooling for our systems. As our material testing machines are engineered and built right here in Norwood Massachusetts, our team can provide engineered to order products including higher force capacity, extended stroke, increased distance between columns and more. Need something special? Just discuss with one of our engineers!

- eXpert 2600 – Equipped with ASTM F519 Hydrogen Embrittlement Testing Fixture

- eXpert 2657 – Interchangeable Fixtures and Accessories

- eXpert 2650 – Tube Furnace (1000° C + Available)

- eXpert 2611 – Webbing Tension Test

- eXpert 2611 – ASTM Puncture Test

- eXpert 2654 – Optional Height Extension

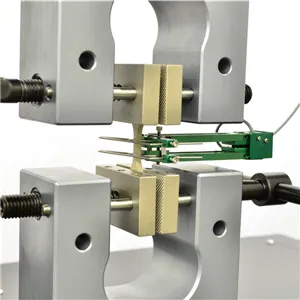

- eXpert 2611 – ASTM D695 Compression Test with Integrated DF-HS Linear Displacement Sensor

- eXpert 2610 with extensometer and removable oven

- eXpert 2657 with Safety Cage

- eXpert 2611 – Polycarbonate Safety Cage

- eXpert 2611 – ASTM D2412 Pipe Compression Test

- eXpert 2611 – Three-Point Wood Flexural Test

- eXpert 2610 – Webbing Tension Test

- eXpert 2613 – GPW-50T Pneumatic Wedge Grips

- eXpert 2654 – GSP-100BT Webbing Grips

- ASTM D1002 lap shear test on an eXpert 2654

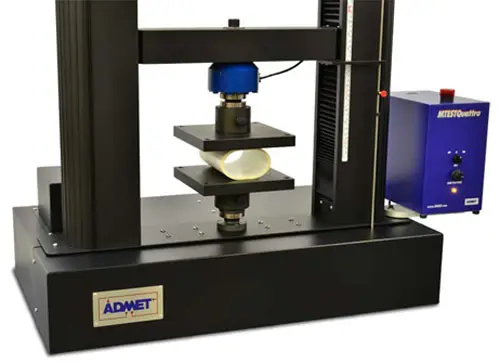

- eXpert 2654 – ASTM C1609 Concrete Test

- eXpert 2600 – Tension Test with Extensometer

- eXpert 2654 – Extended with Watercooled Inserts

- eXpert 2654 – Environmental Chamber

- eXpert 2613 – Dual Testing Space

- eXpert 2613 with Wedge Grips

- Why Tensile Testing is Imperative for Metals Manufacturers

- Sun Path Products Chooses ADMET’S Testing System to Test Parachuting Equipment

- Using Materials Testing to Determine the Strength of Fly Fishing Reels

- Why Choose the eXpert 2600 Series?

- ADMET eXpert 2653 Performs Compression Testing on Desk Chair

- ADMET releases eXpert 2600 for Textile Testing

- ADMET announces eXpert 2600 for Plastics Testing

- ASTM D1708 Plastic Microtensile Testing Equipment

- ASTM F543 Annex 3 Axial Pullout Strength Metallic Bone Screws

- ADMET Introduces Short-Column eXpert 2600ST Series Testing Systems