Universal testing systems may be used to run more than one type of testing. With the appropriate fixturing and controls, you can run tension, compression, and flexion testing with the same universal testing machine. However, for some materials, one type of machine may not provide adequate vertical or horizontal test space, may be too large, and prohibitively more expensive. ADMET Engineering and Software Development teams designed machines configured to test a specific material after working with leading companies within the industry. This blog post covers the common test types and applications to test three different materials: foam, concrete, and elastomers and includes information on the testing equipment, grips, and fixtures configured to measure the mechanical properties of these materials.

Featured Specimen Material: Elastomers

Elastomers are polymer materials that are able to rapidly turn to their initial dimensions and shape after substantial deformation. They are used in a variety of products including automotive, medical, additive manufacturing, packaging, and more.

Tensile testing is the most common test type for rubber or elastomers. Since these specimens often exhibit high elongation, it is important to ensure failure occurs within the measuring range of the testing system.

Featured Equipment: eXpert 7600 XLT Testing Systems

eXpert 7600 XLT testing machines feature the industry’s largest vertical test space, making them ideal for testing high elongation materials such as elastomers. With a pre-set automated controller, the system includes exactly what you need to perform elastomer testing including ASTM D412 and calculate the required tensile stress, strength, and elongation values.

Tensile Grips

It is important to ensure the elastomeric specimen does not slip from the grips. We recommend pneumatic grips and self-tightening eccentric roller grips to clamp elastomers as these types of grips allow maintain a constant clamping force even with significant changes in specimen thickness. Test specimens can be inserted in the grips positioned symmetrically and in axial alignment with the direction of testing. This removes the bending strains that can skew data and is particularly useful when tests are performed in high or low temperatures using an environmental chamber.

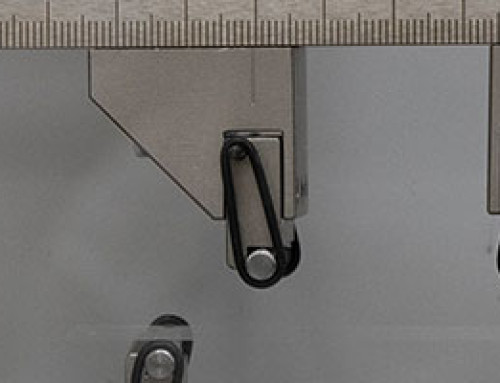

Extensometer

Axial extensometers provide strain data by clamping onto the specimen with their knife edges and measuring the displacement in length as load is applied and the specimen is pulled. Stress vs. strain graphs are among the most common analyses on a tensile test report to evaluate the specimen’s deformation profile and its reaction under applied load. For elastomers, we recommend long-travel axial extensometers. ADMET EX-700CT and EX-110CT extensometer clamps move freely with the specimen and are counterbalanced in order to ensure that the weight of the clamps has no effect on the displacement of the specimen.

Controller & Software

MTESTQuattro controller and software or the eP2 controller and GaugeSafe software may both be used to automate elastomer testing. MTESTQuattro software includes the “go home” feature that allows the testing machine to return to its original position after specimen break, recalling ASTM compatible and user-definable test procedures, and test reports with stress vs. strain curves and a summary of calculated properties.

Featured Specimen Material: Foam

Foam is both a versatile and crucial substance found in a wide variety of products including safety equipment, foam cushions in furniture, mattresses, insulation, sound deadening, carpet padding, shipping & packaging, marine applications, and much more.

Foam manufacturers need to comply with quality requirements showing their products are able to withstand forces acted on them in the real-world use. The most common types of tests run with foam specimens are compression, tension, tear, and recovery testing. Properties such as firmness, stiffness, and load bearing capacity are measured following the Indentation Force Deflection (IFD) method. Specimens are placed and centered in between a set of compression platens and compressed until the selected compression percentage is reached.

In addition to static testing, fatigue testing may be performed on foam samples as performance over a certain amount of time is an important criterion in determining the durability of the final product.

Featured Equipment: eXpert 5600F/5900F Foam Testing Systems

The eXpert 5600F foam testing system can perform IFD tests as well as tensile, compression, elongation, recovery time, and tear measurements. For customers who need to determine the fatigue capabilities of their materials, the eXpert 5900F fatigue foam testing system can perform the same tests as the 5600F testing machine and can also conduct fatigue tests. These machines as well as ADMET’s software exceed international testing standards and can determine ASTM D3574 and ISO 2439 among other foam testing specifications.

All types of foam can be tested on these particular ADMET machines including open-cell, closed-cell, latex, polyurethane, and reticulated.

Compression Platens

A pair of compression platens or T-platens that are wider than the specimen in all directions is recommended for foam specimens. Perforated platens allow the air to escape and are available for foam testing. In addition, some test methods require the use of platens mounted on swivel or universal adapters.

Tensile Grips

Tensile and tear testing of foam requires the use of pneumatic or manual vise grips. Our recommendation is to choose grips that can be manually tightened due to two main reasons: (1) to ensure specimen alignment between the jaws and (2) to adjust the clamping force as needed. Grip jaw surface options include blank, rubber, serrated, and more. For foam, serrated jaws are the most commonly used jaw surface type. Wide tensile grips for holding thicker foam specimens may be chosen depending on the specimen thickness.

Controller & Software

eXpert 5600F and eXpert 5900F foam testing systems feature ADMET’s MTESTQuattro PC-based controller with pre-installed foam test methods and analysis. During an IFD test, the MTESTQuattro software charts live load and foam height over time. A report from the controller consists of the force of deflection, support factor, specimen identifier, load, and time.

Featured Specimen Material: Concrete

Concrete has been in use for construction for over 2,000 years, but modern technology has had a major impact on even a simple material like concrete. In addition to steel reinforcing bar, advanced fibers are used to strengthen concrete in structural applications as well as high temperature/high pressure applications in oil and gas drilling.

The most common types of tests to determine a concrete specimen’s material properties are compression and bend testing. Concrete compression test setups usually involve a high-capacity testing machine equipped with two compression platens, a deflectometer, and displacement transducers. If flexural properties are measured, the concrete testing machine can also be equipped with a high-capacity bend fixture.

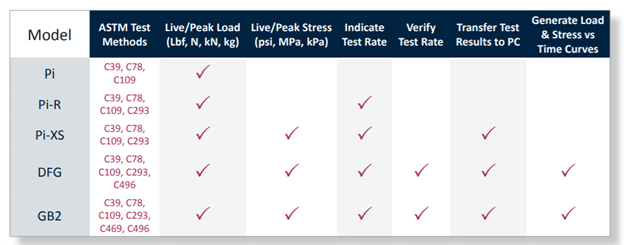

Is Manual or Automated Operation more appropriate for my concrete testing?

Manually operated systems are often sufficient for concrete testing applications. Nevertheless, certain test standards governing the concrete industry require strain rate feedback that is not possible to achieve with manual operation.

For some concrete tests, it is required to have verifiable loading rate throughout the testing as concrete exhibits loading-rate sensitivity relative to compressive strength. Certain ASTM standards, such as ASTM C39, specify or limit the loading rate to a certain value or a range in order to ensure consistency within and among laboratories. When equipped with the right digital indicator, the average loading rate can be calculated and reported according to ASTM C39 requirements even if the testing was performed on a manually controlled machine. In addition to other features specifically beneficial for the concrete industry, depending on the selected digital indicator, load and stress versus time data and curves can be generated.

For others, such as ASTM C1609, it is necessary to maintain a low, constant speed throughout the test. Digital indicators do not control the testing machines, so operators are required to manually adjust a valve to achieve the specified rates. Hence, it is not possible to accurately follow standards that require constant low speed testing with manually operated systems. Servo-control equipment with controllers that are used to control the movement of the machine is recommended for such testing. ADMET offers servo-control testing systems made specifically for concrete testing as well as closed-loop electromechanical and servo-hydraulic universal testing machines that can be used to run a variety of material tests.

Featured Equipment: eXpert 2600 Concrete Testing Systems

eXpert 2600 Concrete Testing Systems are high-force dual column electromechanical frames equipped with the MTESTQuattro controller and software. The force capacity of eXpert 2600 table-top units is up to 100kN (22,500 lbf) while floor standing units can go up to 400kN (90,000 lbf). Concrete testing systems are capable of performing ASTM C39, C78, C109, C469, and C1609 concrete test methods.

Compression Platens

Compression platens mounted on the top and bottom of the concrete testing system are used for concrete testing. The specimen must be carefully aligned with the loading axis prior to applying the compressive force.

Bend Fixture

The most common concrete bend test is ASTM C1609. ADMET’s ASTM C1609 net deflection fixture is engineered specifically per the requirements outlined in the standard. The fixture has a span spacing of 18 inches, as required for 6 by 6 inch beam specimens. In addition, the spacing on the nose side is 6 inches so there is a one third of space in between all contact points on the beam. The fixture includes transducer mounts that are designed to ensure displacement transducers are placed in the center points of the concrete beam specimen.

Compressometer Assembly & Displacement Transducers

ADMET offers compressometer assemblies configured for 3 by 6 in, 4 by 8 in, 6 by 12 in specimens. Mount one or two displacement transducers on the compressometer assembly to determine accurate deformation and strain readings.

For ASTM C1609, two displacement transducers on either side of the beam is required to measure the net deflection. ADMET ASTM C1609 deflection fixture package includes the displacement mount and the two displacement transducers.

Controller & Software

ADMET offers a full range of digital indicators for concrete testing. These indicators can be installed on new machines or retrofitted to existing machines in the field. Indicator selection is dependent on the testing requirements and testing machine.

For more complex tests such as ASTM C1609, we recommend ADMET MTESTQuattro controller and software.

Conclusion

ADMET Engineering and Software Development teams are based off our office in Massachusetts, USA. We developed the testing systems configured for the elastomer, foam, and concrete industries after working with leading companies within each industry and determining their exact needs. Contact us today to see how we can improve your testing process.