In this video, ADMET CEO Richard Gedney guides you through running ASTM C1609 on an eXpert 2655 electromechanical testing machine equipped with MTESTQuattro and a three point bend fixture designed per the standard. This post covers the main points explained in the video.

ASTM C1609 is a test method that evaluates the flexural performance of fiber-reinforced concrete. A load-deflection curve is generated by testing a simply supported beam under third-point loading using a closed-loop, servo-controlled testing system. This test method utilizes two preferred specimen sizes of 4 by 4 by 14 in tested on a 12 in span, or a 6 by 6 by 20 in tested on an 18 in span.

ASTM C1609 Net Deflection Fixture

- The specimen tested in the video is a 6 by 6 inch beam.

- The ASTM C1609 flex fixture has a span spacing of 18 inches, as required for 6 by 6 inch beam specimens. In addition, the spacing on the nose side is 6 inches so there is a one third of space in between all contact points on the beam.

- The first fixture setup shown has the 6 by 6 inch beam mounted into the deflection fixture.

- For ASTM C1609, two displacement transducers on either side of the beam is required to measure the net deflection.

- See video for how the transducers on each side of the beam are mounted to complete the ASTM C1609 fixture setup.

Displacement Transducer Setup

It is important to verify that the probe on the end of the displacement transducer is resting properly against the center plate mounted to the top side of the beam. According to ASTM C1609, at least 0.12 inches of stroke on the transducer is needed. ADMET offers transducers with ¼’’ stroke for ASTM C1609 testing. Make sure that there is enough range and that the displacement sensor is in contact with the specimen prior to starting the test. To do so, the displacement on the screen should be checked and the distance against the mechanical stop of the displacement sensor should be measured (see video).

Once the displacement transducers are verified to be in the correct position, the test can begin. This means bringing the loading noses of the deflection fixture down, in proximity to the specimen. Once started, MTESTQuattro software will initiate the test.

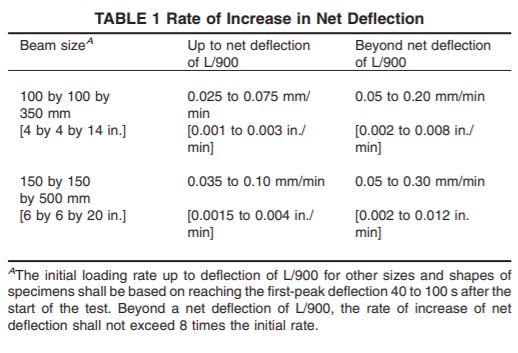

ASTM C1609 Net Deflection Rates

Richard explains that ASTM C1609, Table 1 specifies the test rates, or the net deflection rates, throughout the test. For the first part of the test, which is from 0 deflection to L (span) over 900, the rate for 6 by 6 in beam can vary between 0.0015 in/min to 0.004 in/min. From after L over 900, all the way out to L over 150, the deflection rate can be set from 0.002 in/min to 0.012 in/min. So on this particular task, the rate will be 0.002 in/min until L over 900 and then 0.007 in/min until L over 150.

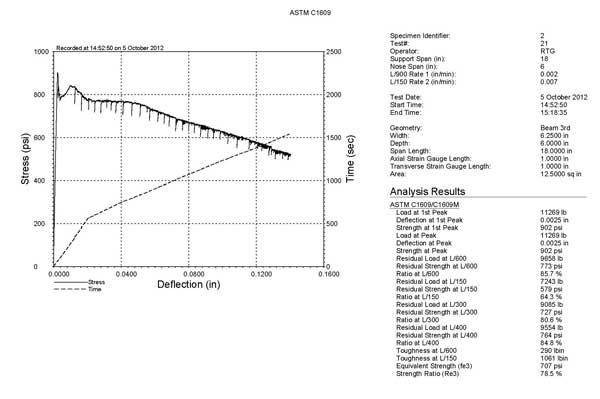

MTESTQuattro ASTM C1609 Test Report

The video shows the initial loading, and within the first minute, the first crack occurs. The test continues at 0.002 in/min until L over 900. Once L over 900 is reached, software will automatically increase the net deflection rate to 0.007 in/min and this will continue until L over 150. The test is then completed and the ASTM C1609 results report is generated.

Recommended Equipment

ASTM C1609 specifies that the test must be performed in servo control at very slow net deflection rates. ADMET is one of the only testing machine manufacturers in the world that offers equipment to perform this demanding standard. Almost all C1609 tests can be performed on a 100kN (22,500 lbf) testing machine. ADMET offers a complete C1609 test package which includes our eXpert 2654 Dual Column Testing Machine equipped with the MTESTQuattro® Materials Testing System and the 3-point bend fixture with associated transducers to measure net deflection.

For more information, please visit our CONCRETE TESTING webpage.