ASTM C1609 | Concrete | Bend Testing

Fiber reinforced concrete (FRC) is finding increased use in construction. FRC offers several advantages over rebar or wire mesh reinforced concrete including increased crack resistance, ductility, energy absorption, impact resistance and residual strength. FRC can also significantly lower materials and labor costs compared to rebar or wire mesh reinforced concrete. The strength of FRC is strongly dependent on the type, size, shape, and amount of fiber used, and testing is required to determine the correct proportions for each application. ASTM C1609 describes the methodology for testing the flexural strength of rectangular FRC beams with dimensions of either 4 x 4 x 14 inches or 6 x 6 x 20 inches.

A mechanical testing machine equipped with the appropriate bend fixture, two displacement transducers, and software capable of controlling the test and recording/analyzing the data is required. The test machine operates in compression at very slow test speeds under closed loop deflection rate control. Electro-Mechanical testers are preferred for control at these test speeds.

A “third-point loading” fixture is used with two support points below the beam and two loading noses on the top of the beam. A fixture is mounted on the beam’s neutral axis directly over the supports.

Read more about changes to the ASTM C1609 test fixture here.

Two displacement transducers, one on each side of the beam, are mounted to the jig mid-span to measure beam deflection. The outputs of the transducers are averaged together to provide the net deflection measurement. This configuration ensures accurate measurement of mid-span deflection and minimizes errors due to concrete specimen twisting or seating in the supports.

Changes to the ADMET’s ASTM C1609 three-point bend fixture include:

- Loading nose designed per ASTM C78

- Bottom brackets designed according to ASTM C1812

For a summary of the test, click the Testing Procedure tab. If you need to perform these tests, please read the entire specification from the relevant ASTM publication.

ASTM C1609 | Concrete | Bend Testing

- Prepare the specimen carefully and measure and record the specimen dimensions prior to the test

- Mount the frame with the deflectometers on the sample. Ensure that there is enough travel for them to record the sample deflection at the mid-point.

- Load the specimen on the third-point loading fixture as shown in the attached pictures and videos.

- Run the test at the specified net deflection rates (based on beam length “L”) as measured at the mid-span point of the beam.

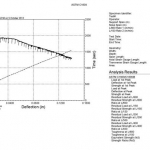

- Record and report the parameters as listed below.

- Load at 1st Peak

- Deflection at 1st Peak

- Strength at 1st Peak

- Load at Peak

- Deflection at Peak

- Strength at Peak

- Toughness at L/600

- Toughness at L/150

- Equivalent Strength (fe3)

- Strength Ratio (Re3)

- Residual Load at L/600

- Residual Strength at L/600

- Ratio at L/600

- Residual Load at L/150

- Residual Strength at L/150

- Ratio at L/150

- Residual Load at L/300

- Residual Strength at L/300

- Ratio at L/300

- Residual Load at L/400

- Residual Strength at L/400

- Ratio at L/400

ASTM C1609 | Concrete | Bend Testing

- ASTM C1609 Fixture on eXpert 2657

- eXpert 2657 (300 kN) – With ASTM C1609 fixturing and optional computer

- ASTM C1609 Fixture with Displacement Transducer

- MTESTQuattro Test Report for ASTM C1609

ASTM C1609 | Concrete | Bend Testing

| ASTM C1609 | Recommended Equipment |

|---|---|

| Testing System | |

| Fixturing | |

| Accessories |