Hydraulic eXpert 1000 | Capable and Reliable

ADMET’s hydraulic eXpert 1000 Series testing machines are ideal for testing metals, composites, medical devices and implants, concrete, webbing, and other materials at very high load capacities without breaking your budget. Each frame employs strain gage load cells for direct measurement of force. No need to compensate for piston friction and other non-linearities, these frames offer exceptional accuracy and precision while reducing long-term calibration and service costs. A simple design based upon off-the-shelf components allows for lower cost, faster delivery, continuous testing to maximum load, and years of maintenance free operation. The hydraulic power supply and electronics are integral with the frame thereby saving valuable lab space.

eXpert 1600 Series hydraulic testing frames are capable of performing static tension, compression, and bend tests. eXpert 1900 Series dynamic fatigue testers are engineered to meet the force-stroke-frequency requirements of your application. ADMET offers a full line of hydraulic testing grips, fixtures, load cells, extensometers and heating and cooling systems. All ADMET hydraulic testing machines can be modified to satisfy special stroke, load, and fixturing requirements.

- eXpert 1912 with Customer 4-point Bend Fixture

- eXpert 1912 – Four Point Bend Fatigue Demo

- eXpert 1600 UTM – Wedge Grips

- eXpert 1900 with Hydraulic Grips

- eXpert 1600 UTM – Environmental Chamber

- eXpert 1900 UTM – Hydraulic Fatigue Tester

- eXpert 1600 UTM – Custom Inverted Compression Test Machine

- eXpert 1900 UTM – Fatigue Testing

- eXpert 1600 UTM – Custom Frame

- Shear Testing on an eXpert 1600

- eXpert 1600 UTM – Bend Testing

- eXpert 1600 UTM – Threaded End Grips

- eXpert 1600 UTM – Furnace with Water Cooled Couplings

- eXpert 1600 UTM – Custom Horizontal Frame

- eXpert 1655 UTM – with safety cage

- eXpert 1655 – Equipped with combination wedge grip/compression platen fixture

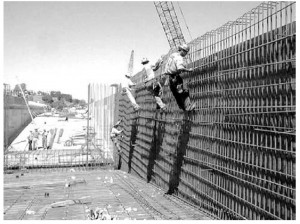

- Can I automate ASTM A370 to test rebar?

- Do I retrofit or replace my hydraulic universal testing machine?

- ASTM F2634 Polyethylene Butt Fusion Joint Test Testing Equipment

- BarronCast Uses ADMET System to Bring Mechanical Testing In-House

- Niacc-Avitech Technologies Uses ADMET ExPress for Aircraft Shock Absorber Servicing

- University of Connecticut Connecticut Transportation Institute uses the ADMET eXpert 1655 Hydraulic UTM for crack propagation testing of RFID-based crack sensors

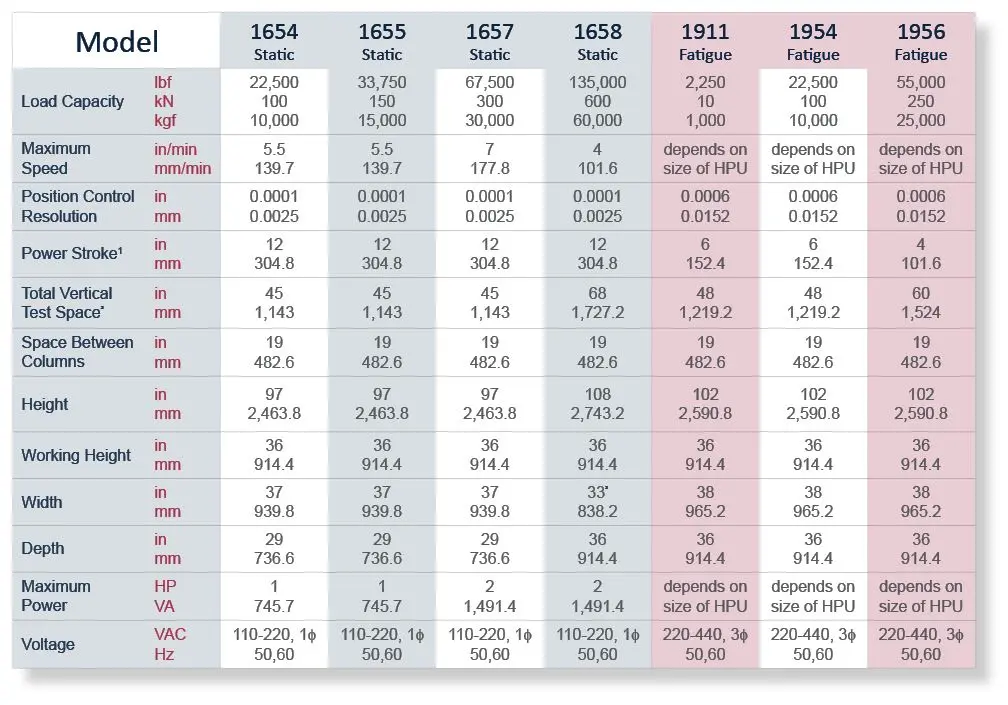

eXpert 1000 specifications

Featured Configurations

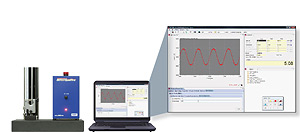

eXpert 1000 Metal Testing System

The ADMET eXpert 1000 series are servohydraulic testing systems widely used to test metal products at very high load capacities. The ASTM E8 configuration was supplied with wedge grips and an axial extensometer as specified in the standard test method. The system was equipped with the ADMET MTESTQuattro controller and software for automated calculations of the yield strength, ultimate tensile strength, percent elongation, and more.

- Axial force capacity up to 300kN (67,500lbf)

- Includes wedge grips and extensometer for ASTM E8 Metals Testing

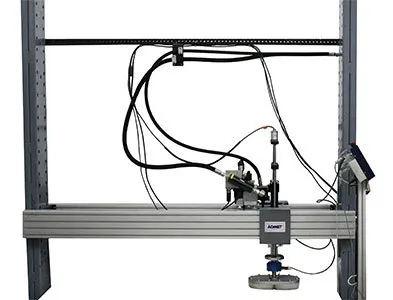

eXpert 1000 Cornell Mattress Testing System

ADMET works with foam and mattress manufacturers to help ensure the quality of their products. The featured configuration was built to run ASTM F1566 Cornell Testing on mattresses up to and including King size. ADMET eP2 controller is preloaded with test procedures to perform the entire Cornell Test without any operator interaction. The servohydraulic actuator can be manually moved along the cross beam in order to initiate testing at different (infinite) locations along the width of the mattress.

- Capacity up to 5kN (1,000lbf)

- H-series floor standing custom mattress compression testing frame with Cornell compression platen

- Automatic calculation of Support Firmness and Dimple values

eXpert 1900 Fretting Fatigue System

The ADMET eXpert 1900 series configuration was supplied with a fretting fixture to evaluate the effect of a mean bulk load on the fretting fatigue life of metal alloys. The fretting fixture included clamp collars and carriages with mounts for fretting pads. An extensometer was included to measure the relative motion between the fretting pad and the test specimen. The system was supplied with ADMET MTESTQuattro controller with the ability to perform 2nd axis of control for biaxial testing in addition to cyclic fatigue testing.

- Fatigue frame capacity up to 250kN (56,200lbf), Torque capacity up to 100Nm( 885 lbf-in)

- Includes hydraulic grips, fretting fixture, miniature axial extensometer

- Biaxial add-on for axial-torsion testing