Test method ASTM F2634 is used to determine the quality of polyethylene (PE) butt fusion joints. This test is desinged for pipes with a diameter greater than 2.37″ and a wall thickness greater than 0.25″.

Test Summary:

In this test a PE “dogbone” shaped specimen is pulled in tension at a rate of 4-6 inches per second. The specimen has holes on each end which allows them to be pinned to the upper and lower crosshead. The speed of this test is quite fast and the fixturing provides clearance to allow the machine to quickly gain enough speed before the impact takes place. After the test, the following are typically reported:

- Yield Energy

- Average Rate of Speed

- Recorded force / vs time chart

- Max force

- Rupture energy

- Yield stress

- Type of rupture

Equipment required:

- Testing machine with a controlled rate of crosshead movement (constant rate of extension)

- Speed of 6 inches per second (360 inches per minute)

- Data acquisition rate of 1000 HZ (1000 samples per second)

- Load cell

- Fixturing to provide impact clearance and hold samples

- Position indicator (LVDT, encoder, extensomer, etc.

Equipment available:

McElroy, a company that designs and manufactures a complete line of fusion equipment, makes a machine specifically for this test called the McSnapper. It looks nice but we don’t know anything about it.

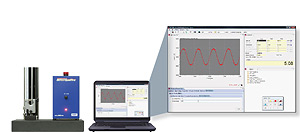

At ADMET we studied ASTM F2623 and determined that our ExPress line of hydraulic universal testing machines offer the best solution for this test. A standard ExPress system with a modified pumping system to increase the maximum speed would satisfy all requirements of the specification.

This is our recommended system:

- Express hydraulic universal testing machine. For example, the Express 50kN would have the following specifications:

- Capacity: 50kN (11,250 LB)

- Power Stroke: 4 inches (Other Stroke Lengths Are Optional)

- Tension Opening: 38.5 inches without load cell.

- Crosshead Thickness: 4 inches

- Speed (max): 165 mm/sec (6.5 inches/sec)

- Column Separation: 508 mm (19 inches)

- Column Diameter: 63.5 mm (2.5 inches)

- Dimensions:

- Height: 2,362 mm (93 inches)

- Width: 838 mm (33 inches)

- Depth: 813 mm (32 inches)

- Power: 220/440 VAC Three Phase

- MTESTQuattro testing software

- ASTM F2634 pre loaded test method and software analysis module

- ASTM F2634 fixturing