ADMET has been serving companies in the metals industry for decades. We’ve helped hundreds of companies solve their physical testing challenges when it comes to metal testing applications, from large structural elements to very small medical devices. Whatever your testing application, we want to help you succeed.

We’ve written several blog posts on topics relevant to professionals in the metals industry who want to ensure their materials meet or exceed the desired specifications. Check out the articles below to learn more about key concepts in metals testing and to see recommended systems from ADMET for the metals industry.

Metals Tensile Testing Concepts, Equations, And Theory

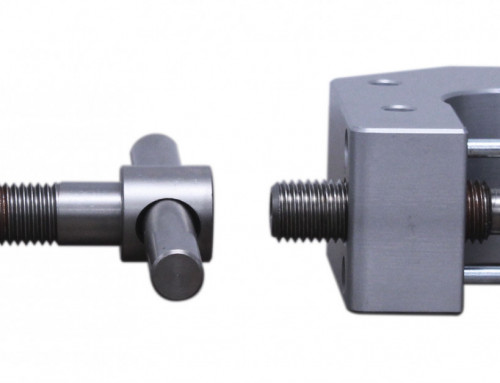

Our comprehensive blog post on metals tensile testing covers core concepts like strength, ductility, and elongation, and goes into details on specific equations that are needed to determine stress-strain curves. It also includes helpful information on recommended equipment needed to perform metals tension tests quickly and accurately. Read the article here.

Sheet Metal Tension Testing

The mechanical properties of the sheet material greatly influence its formability, which is a measure of the amount of deformation the material can withstand prior to fracture. This blog post covers important definitions determining sheet metal characteristics, the test methods, and the equipment used to quantify them. Read the article here.

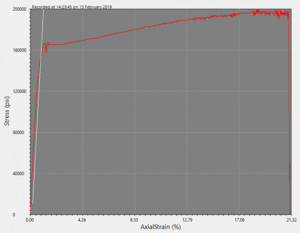

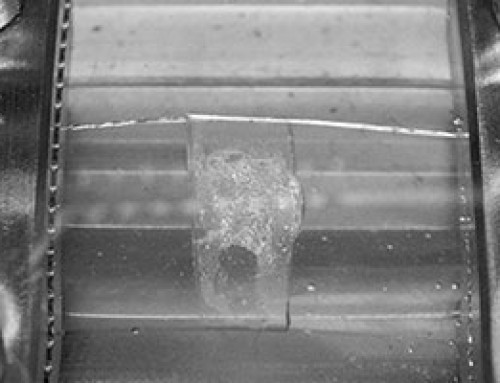

Lüders Bands Phenomenon in ASTM E8 Tensile Testing

Some metals, particularly annealed low-carbon steel, or mild steel, show a discontinuity when transitioning from elastic to plastic deformation that produces the yield point phenomenon in the stress strain curve. Learn more about this phenomenon in our blog post. Read the article here.

Let's discuss your metals testing equipment needs.

Our engineers will recommend a solution that fits your specific requirements.