ADMET: Your Comprehensive Solution for Concrete Testing

From manual systems to fully automated solutions, ADMET offers a diverse range of equipment tailored to meet your concrete testing needs. Our offerings include:

- Indicators: Complementing existing manual systems for precise measurements.

- Controllers: Seamlessly retrofitting servo-control machines for enhanced performance.

- MegaForce Concrete Testing System: Designed specifically for concrete testing applications.

- Electromechanical & Hydraulic Servo-Control Machines: Versatile platforms for conducting a variety of concrete tests while ensuring accurate and repeatable results.

Beyond our standard offerings, ADMET is committed to providing customized solutions that align with your unique requirements. Let us help you optimize your concrete testing processes with innovative equipment and expert support.

Digital Indicators for Manually-Operated Concrete Testing Systems

Pi Indicators

Elevate the performance of your manually-operated testing systems with ADMET’s Pi indicators. These versatile devices connect seamlessly to load cells or pressure transducers, providing precise measurements and essential data.

Pi Peak Load Indicator

Key Features:

- Clear Display: 16-character display for easy readability.

- Intuitive Operation: Three-button keypad for simple navigation.

- Accuracy: Exceeds ASTM E4 force accuracy requirements.

- Versatility: Available in three models to suit your specific needs.

Pi Models:

- Pi: Displays peak load in selectable units (lbf, N, kN, kgf). Ideal for ASTM C39, C78, and C109 tests.

- Pi-R: Provides load rates in addition to peak load, making it suitable for ASTM C293 calculations.

- Pi-XS: Offers peak load, load rate, stress, and stress rate measurements, supporting ASTM C39, C78, C109, and C293.

GaugeSafe Data Exchange (Optional for Pi-XS):

Enhance your Pi Indicator’s data management capabilities with GaugeSafe Data Exchange software. Access live numerical data and visualize test results on your PC for in-depth analysis and reporting.

DFG Concrete Indicator: A Specialized Tool for Concrete Testing

DFG Concrete Indicator

Designed with concrete testing applications in mind, the DFG Concrete Indicator is the successor to ADMET’s original GaugeBuster indicator. This specialized device provides comprehensive test data, including:

- Peak Load and Stress: Accurate measurements for critical analysis.

- Specimen Details: Geometry, dimensions, date, time, and specimen number for complete identification.

- Calculated Parameters: Average rate of loading and cylinder correction factor for streamlined reporting.

- Operator Input: Operator ID, specimen weight, and age for traceability.

- Failure Analysis: Cylinder break type and cap type for detailed evaluation.

Predefined Specimen Geometries:

The DFG features predefined specimen geometries to simplify stress calculations:

- Cylinder

- Cube

- Beam (center point loading)

- Beam (3rd point loading)

- Round cross-section

- Rectangular cross-section

GaugeSafe Data Exchange (Optional):

With ADMET’s GaugeSafe Data Exchange software, you can seamlessly integrate your DFG indicator to export test data, generate comprehensive reports, and conduct in-depth analysis.

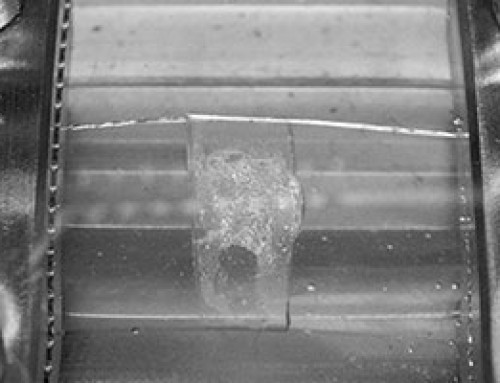

GaugeBuster 2 and 3: Versatile Indicators for Diverse Testing Needs

The GaugeBusters are highly adaptable indicators available in various sizes to suit your specific requirements. Their modular design allows for customization with additional features and channels, expanding their capabilities beyond basic load and stress measurements.

For concrete testing applications, the GaugeBuster’s optional auxiliary (encoder) and strain (analog) channels enable advanced testing, such as ASTM C469. In combination with ADMET’s compressometer-transducer assembly, you can accurately calculate axial and transverse strain for ASTM C469, Poisson’s ratio, and Young’s Modulus testing.

Gauge Buster 2 Advanced Indicator

Enhancements for Data Management:

- Printer Port: Directly connect your GaugeBuster 2 or 3 to a printer for immediate hard copies of test data and results.

- USB Flash Drive Port: Save test results, XY data, test settings, and calibration tables onto a flash drive for convenient storage and transfer.

GaugeSafe Software Options:

Choose the GaugeSafe software package that best aligns with your needs:

- GaugeSafe Basic: Provides numerical test results for essential data.

- GaugeSafe Plus: Offers numerical values and graphs for visual analysis.

- GaugeSafe Live: Displays live test data and graphs throughout the testing process.

With GaugeBuster indicators, you have the flexibility to tailor your testing system to meet your specific requirements, whether it’s for basic load measurements or advanced concrete testing applications.

MegaForce Concrete Testing System: Accuracy and Precision

Concrete cylinder testing per ASTM C39 on MegaForce

The MegaForce Concrete Testing System was designed to overcome the limitations of manually-operated systems and the high costs associated with traditional servo-hydraulic testing equipment. By retrofitting existing compression machines with MegaForce, you can automate control and operation for various testing standards, including ASTM C39, C109, C469 and EN 14651.

Key Benefits:

- Enhanced Precision: Maintain consistent load, position, or strain control throughout your tests.

- Increased Efficiency: Automate the testing process, reducing manual effort and errors.

- Cost-Effective Solution: Upgrade your existing equipment without breaking the bank.

Compatible with Compression Machines:

The MegaForce system is compatible with compression machines capable of up to 69 MPa or 10,000 psi and more.

Automated Reporting:

Choose from a range of compatible indicators to generate automated compressive strength test reports. This eliminates the time-consuming and error-prone process of manual reporting.

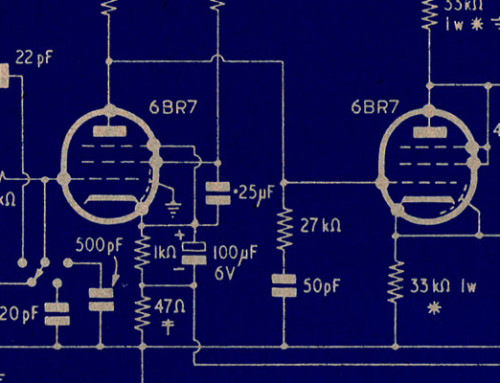

Universal Testing Systems: A Versatile Solution

For complex calculations, precise control, and the ability to conduct tensile or high-capacity tests, universal testing machines are indispensable. ADMET’s versatile systems offer a comprehensive solution for concrete testing, including tension, compression, and flexion with automated control and strain-rate feedback. These machines are ideal for standards like ASTM C307, C469, C1609, and EN 14651.

eXpert 2600 configured for ASTM C1609 Concrete Bend Testing

Electromechanical Testing Systems: Precision and Efficiency

The eXpert 2600 electromechanical testing systems offer a compact and powerful solution, available in tabletop or floor-standing configurations up to 400kN (90,000 lbf). The servo-control motor enables precise testing at slow deflection rates, making them suitable for complex standards like ASTM C1609.

ADMET’s eXpert 1000 series Hydraulic testing machines

Servo-Hydraulic Testing Systems: High Capacity and Versatility

The eXpert 1600 servo-hydraulic testing systems provide exceptional performance for tension, compression, and flexion tests up to 600kN (135,000 lbf). A wide range of accessories, including compression platens, the ASTM C469 assembly, and ASTM C1609/EN 14651 bend fixtures, ensures versatility for various testing needs.

Industries Benefiting from Universal Testing Systems:

Industries such as oil & gas, mining, and downhole cementing often require a wide range of precision tests. ADMET’s eXpert 1657 Servo Hydraulic Test System offers an efficient and cost-effective solution for these demanding applications.

Conclusion

ADMET offers a comprehensive range of concrete testing equipment, from manual systems to fully automated universal testing machines. Whether you need basic measurements or advanced analysis, our solutions are designed to meet your specific requirements. With our commitment to quality, innovation, and customer support, ADMET is your trusted partner for reliable and efficient concrete testing.

Contact us today to find the right concrete testing solution.

We’re standing by to help you find the right equipment for your needs.