Structural Engineering Reports are insightful reports prepared by a professional engineer that check for potential damages by evaluating property structures and substructures, identify the root cause of damage, and provide recommendations on foundation repairs.

Three years before the catastrophic collapse of the Champlain Towers South condominium complex near Miami, engineering reports recommended extensive repairs to maintain the structural integrity of the building. Damages reported included concrete deterioration, rebar damage, crumbling of the columns, beams and walls of the parking garage under the building. Some of the identified root causes of damage were persistent water leakage and exposure to environmental conditions such as the corrosive salt air.

Concrete Testing

Concrete has been in use for construction for over 2,000 years, but modern technology has had a major impact on even a simple material like concrete. In addition to steel reinforcing bar, advanced fibers are used to strengthen concrete in structural applications as well as high temperature/high pressure applications in oil and gas drilling.

Fresh & Hardened Concrete Testing and Evaluation

When concrete is fresh and first poured, concrete strength and cracking properties should be assessed as test data can help overcome potential issues that may arise in the future. Typical fresh concrete tests not only identify the air content, density, and temperature of fresh concrete samples, but also provide information on proper sampling of freshly mixed concrete and curing concrete test specimens in the field.

Next, hardened concrete samples should be tested in order to properly examine the concrete strength as well as durability, such as surface scaling. This stage involves procedures such as microscopic examination of the air-void system of hardened concrete, measuring the concrete thickness using drilled concrete cores and more.

Laboratory Concrete Testing and Evaluation

The initial testing of concrete is based on theory-based methods to evaluate properties and determine the correct concrete sample use in its distinct application in the environmental conditions concrete will be poured in. For example, results obtained from testing the compressive strength of concrete are used as a basis for quality control of concrete proportioning, mixing, and placing operations. Compressive strength values change based on the size/shape of the specimen, batching, sampling, molding, as well as the age, temperature of concrete and moisture conditions.

Flexural strength, also expressed as Modulus of Rupture, is the ability of a beam to resist failure in bending. Concrete specimens undergoing flexural tests exhibit instantaneous tensile failure. Modulus of Rupture measurements are often used in research and in laboratory evaluation of concrete ingredients and proportions though some beam specimens should also be tested for both flexural and compressive strength in the field.

Modulus of Elasticity and Poisson’s ratio testing is performed on different concrete mixes poured into concrete cylinder specimens. Modulus of Elasticity for concrete varies based on the aggregate and mixture proportions of the concrete and the mixture exhibiting a high Modulus of Elasticity is not necessarily the same mixture exhibiting a high compressive strength. On the other hand, Poisson’s ratio is insensitive to both the age and the richness of the concrete mix. Both properties should be tested to evaluate potential deflections, which are proportional to the stiffness of concrete, in a certain concrete mixture.

Common testing standards for concrete include:

Concrete Testing Equipment

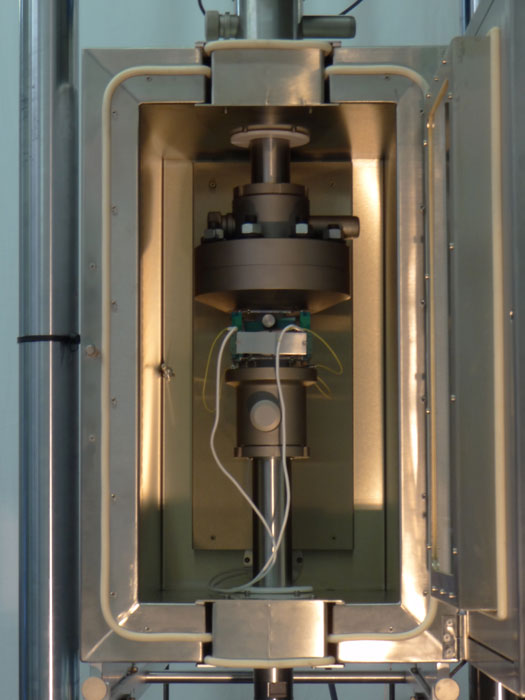

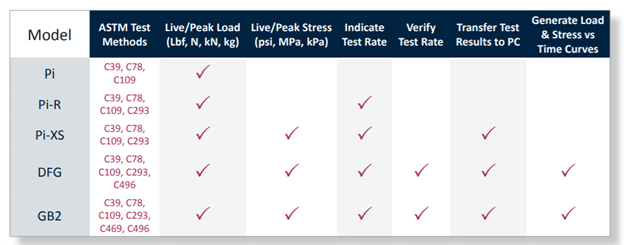

Manually operated systems are often sufficient for concrete testing in laboratory settings. ADMET offers a full range of digital indicators made for concrete testing applications that can be installed on manually operated machines or retrofitted to existing machines (manual and servo-controlled) in the field. Indicator selection is dependent on the testing requirements and the testing machine.

For some concrete tests, it is required to have verifiable loading rate throughout the testing as concrete exhibits loading-rate sensitivity relative to compressive strength. Certain ASTM standards, such as ASTM C39, specify or limit the loading rate to a certain value or a range in order to ensure consistency within and among laboratories. When equipped with the right digital indicator, the average loading rate can be calculated and reported according to ASTM C39 requirements even if the testing was performed on a manually controlled machine. In addition to other features specifically beneficial for the concrete industry, depending on the selected digital indicator, load and stress versus time data and curves can be generated.

For others, such as ASTM C1609, it is necessary to maintain a low, constant speed throughout the test. Digital indicators do not control the testing machines, so operators are required to manually adjust a valve to achieve the specified rates. Hence, it is not possible to accurately follow standards that require constant low speed testing with manually operated systems. Servo-control equipment with controllers that are used to control the movement of the machine is recommended for such testing. ADMET offers servo-control testing systems made specifically for concrete testing as well as closed-loop electromechanical and servo-hydraulic universal testing machines that can be used to run a variety of material tests.