Peel Testing Universal Testing Systems

ADMET offers a variety of peel testing machines that are ideal for measuring the peel strength of elastomers, adhesives, glues, cement, laminates, packaging, fabrics, coatings, labels, tapes, medical devices, and other products, materials, and components. With an ADMET system, you can accurately calculate the average peel strength load over a specified distance and strength per unit width of adhesive. All adhesive testing systems feature constant-rate-of-extension (CRE) and constant-rate-of-load (CRL) control which allows you to perform a wide variety of adhesive tests with only one testing machine.

Peel strength is the average load per unit width of the bond line required to gradually separate a flexible member from a rigid member over adhered surfaces. It is calculated by measuring the average force required to peel the sample divided by the bond (i.e. adhesive) width. Peel strength is expressed in the following units: kilograms per millimeter (kg/mm) or pounds per inch (lb/in). Where

The type of peel test used to determine peel strength is based on material geometry, industry, and material applications. The angle between members varies on the type of test performed. ADMET can help determine what type of peel testing is suitable for your peel testing needs.

Common Peel Testing Types:

- T-Peel Test: Used for measuring the peel separation strength of two flexible materials that have been bonded together

- 90-Degree Peel Test: Used for measuring the peel strength of a flexible material adhered to a specific substrate at 90 degrees

- 180-Degree Peel Test: Similar to the 90-degree peel, the flexible material is adhered to the substrate but is peeled at 180 degrees

- Floating Roller Peel Test: Allows for a material to be peeled gently, it is ideal for materials that are unable to bend to a 90-degree or 180-degree angle.

- Climbing Peel Drum Test: Used to measure the peel resistance of two materials with different material properties, the climbing drum ensures a pure “peeling” force on the sample.

- Loop Tack Strength Test: Used to measure the tack force/strength of a pressure-sensitive adhesive (PSA).

ADMET offers the fixtures required to perform peel testing outlined above. More details can be found on our Peel Testing Fixtures Page.

Common Peel Testing Standards:

ADMET systems and fixtures can perform peel tests (but are not limited) to the following standards.

- ASTM D903 – Standard Test Method for Peel or Stripping Strength of Adhesive Bonds

- ASTM D1781 – Standard Test Method for Climbing Drum Peel for Adhesives

- ASTM D1876 – Standard Test Method for Peel Resistance of Adhesives (T-Peel Test)

- ASTM D3167 – Standard Test Method for Floating Roller Peel Resistance of Adhesives

- ASTM D3330 – Standard Test Method for Peel Adhesion of Pressure-Sensitive Tape

- ASTM D6195 – Standard Test Methods for Loop Tack

What equipment do I need to perform peel testing?

To perform peel testing, you will need a testing frame, a peel testing fixture or vise grips, a load cell, and a controller. The type of peel fixture and testing frame required will be dependent on the type of peel test and material geometry and properties. ADMET can provide all of the equipment required for you to perform peel testing at your facility.

Recommended Equipment: Testing Frame

Due to the relatively low forces required to perform peel testing, the majority of peel tests can be performed on the ADMETs eXpert 7600 or eXpert 5000 series Universal Testing Machines.

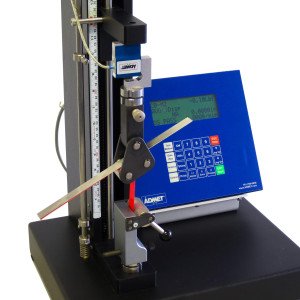

eXpert 7600 Single Column Testing Machine

The eXpert 7600 is a popular peel-testing machine due to its ability to produce accurate results in an affordable and compact package.

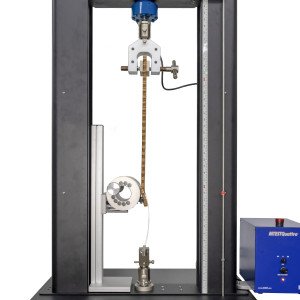

eXpert 5000 Modular Testing Machine

The eXpert 5000 series testing machines feature configurable frame components and a detachable actuator, giving you the ability to configure your system in a variety of vertical or horizontal orientations.

Custom Peel Testing Systems

Do you require a customized peel testing solution? ADMET Engineers will work with you to design the right system to meet your material testing needs.

Work with our engineers to design a custom solution for your application.

Recommended Equipment: Peel Test Fixture

ADMET’s easy-to-use adhesive peel fixtures are employed by the adhesive industry to test the peel strength, bonding, and shear properties of adhesives. Peel fixtures conform to testing standards such as ASTM D1781, ASTM D3330, ASTM D3167 and can also be customized based on your test application. Below we will explore the types of peel tests and the required fixturing to perform them.

90 Degree Peel Fixture

Requires FS-PL-90 fixture and a vise grip or eccentric roller grip.

180 Degree Peel Fixture

Requires two vise grips and a rigid test substrate.

Floating Roller Peel Fixture

Requires an FS-PL-ASTM D3167 floating roller and a vise grip or eccentric roller grip.

Climbing Peel Drum Fixture

Requires an FS-CDT-ASTM D1781 and a vise grip or eccentric roller grip.

T Peel Fixture

Requires two vise grips and a flexible substrate.

Loop Tack Strength Fixture

Requires a vise grip and a cube fastened to the bottom of the testing machine.

Peel Testing Videos

Checkout our peel testing playlist on Youtube or see our peel-testing videos below.

Peel Testing Articles

- Peel Strength Testing

- ASTM D903 Peel or Stripping Strength of Adhesive Bonds How to Guide

- How to Perform an Adhesive Strength T-Peel Test — ASTM D1876

- 90 Degree Adhesive Peel Strength Test on a Universal Testing Machine

- How to Perform an Adhesive Loop Tack Strength Test — ASTM D6195

- ASTM D3330 Peel Adhesion of Pressure Sensitive Tape How to Guide

- Package Seal Tensile Test — 180 degree peel — ASTM F88

- Performing an ASTM D3167 Adhesive Floating Roller Peel Test