The floating roller peel test is one of many types of tests designed to measure the average peel force of an adhesive or other bonding agent. The other common peel tests are the 90 degree, 180 degree, and T-Peel. Although not suitable for every application, the floating roller is a very accurate and easy method to obtain average peel force values.

How do I know which peel test is best for my application?

There are two primary reasons. The first is that you want to test using a method that simulates the end use of your product. For example, when you peel a label off a product, you pull it off at an approximately 90 degree angle. Therefore, you should perform a 90 rather than a 180 degree peel. The second reason is that your materials may only lend themselves to certain types of tests. For example, a T-Peel test is used when both bonded substrates are flexible. This rules out the floating roller, 90 and 180 degree peel test. Each of those tests requires that one of the layers be rigid.

Why perform the floating roller peel test over the 90 or 180 degree peel?

All of these tests are very similar in that they separate a relatively flexible substrate that has been bonded to a rigid substrate. The 180 degree peel test means what it says – the flexible substrate is peeled at a 180 degree angle to the rigid substrate. The same for the 90 degree peel test. However, the floating roller allows the flexible substrate to be pulled apart gently from the rigid substrate as they are being separated over a 1″ mandrel. This is accomplished by using a specially designed floating roller peel fixture. The angle of separation is very gentle so it works well when the flexible substrate is not really that flexible and can’t be bent to a 90 or 180 degree angle.

Video of the test:

What is needed to perform this test?

- A universal testing machine (tensile testing machine)

- Needs to maintain a test speed of 6 inches per minute

- Load of the test should fall within 15 and 85% of the full scale machine capacity.

- The ADMET eXpert 7601 is one machine that is great for tests under 1kN of force (225 pounds). Sometimes this test is performed on a ADMET eXpert 2611 with 10kN (2000 pounds) of capacity.

- One tensile grip to hold the free end of the peel. We commonly use an easy to use self tightening tensile grip.

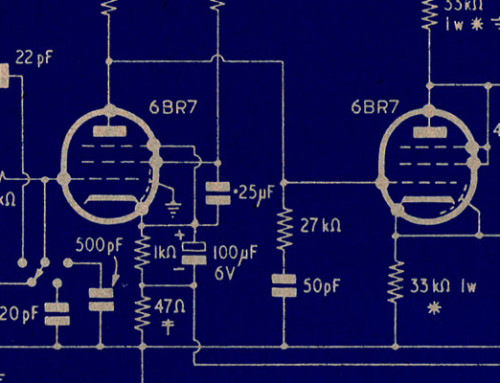

- A Floating Roller Peel Fixture (see below)

Test Setup:

ADMET D3167 “FS-ARPT” Floating Roller Peel Fixture: