Summary of Test

Summary of Test

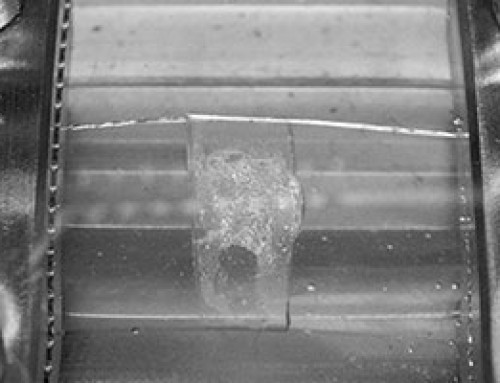

ASTM A370 is performed by steel manufacturers and commercial and government laboratories serving the construction industry to measure the strength of rebar. Values of ultimate tensile strength, yield and elongation are required for the most common sizes.

Why is it done?

Steel manufacturers are required to test the products they sell to ensure that the specifiction cited is met. Significant liabilities can result from providing noncompliant product. Tensile testing to failure is the most common method employed. These often include the use of extensometers for the measurement of Yield.

In the United States, the size designations of these mild steel bars used to reinforce concrete are set by ASTM International. Rebar is generally supplied in 20- and 60-foot lengths.

Most bars are “deformed,” that is, a pattern is rolled onto them which helps the concrete get a grip on the bar. The exact patterns are not specified, but the spacing, number and height of the bumps are. ASTM A615 defines these markings.

Typical deformed reinforcing bar (courtesy of Concrete Reinforcing Steel Institute)

Three grades are defined:

| Inch-pound Grade |

Metric Grade |

Minimum Yield Strength | |

| Pounds per Square Inch |

Megapascals | ||

|

Grade 40 |

Grade 280 |

40,000 |

280 |

|

Grade 60 |

Grade 420 |

60,000 |

420 |

|

Grade 75 |

Grade 520 |

75,000 |

520 |

The size designations up through size 8 are the number of eighths of an inch in the diameter of a plain round bar having the same weight per foot as the deformed bar. So, for example, a number 5 bar would have the same mass per foot as a plain bar 5/8 inch in diameter.

Users of rebar are required to test the rebar they receive using independent sources prior to acceptance. There have been issues with substitution of grades and materials not meeting the intended specification. Testing helps to minimize the possible installation of out of spec rebar.

Why is it important?

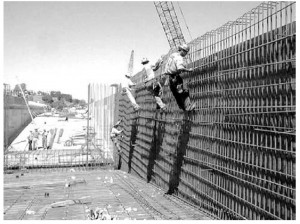

The strength of rebar is a fundamental requirement in the design and construction of buildings, dams, bridges, roads and airports. The failure of a single rebar may result in significant loss of strength in the structure under construction with the possibility of catastrophic failure.

Rebar installation (courtesy HDR Engineering)

What ADMET equipment is needed?

Many steel manufacturers and independent testing laboratories own tensile testing machines of considerable force capacity. These older machines constitute a considerable investment so automating an existing system via upgrade/retrofit is a prudent decision. The upgrade/retrofit is performed at the customer’s site including training.

If new equipment is desired, ADMET ExPress servohydraulic testing machine of capacities 20,000 to 300,000 LBF depending upon rebar size and specification are available.

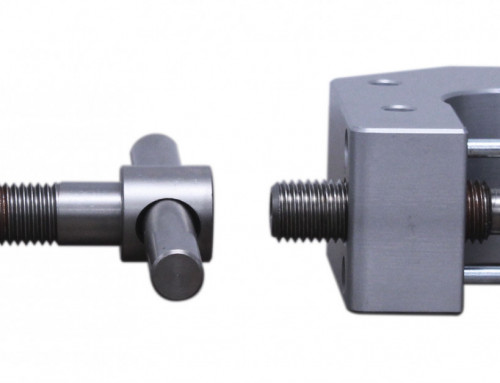

Rebar fixtures including holders and long gauge length extensometer are among the tools ADMET offers for the testing of rebar.

Changes in the force rate being applied to the rebar can affect the yield strength, tensile strength and elongation values which are highly strain rate sensitive. In general the yield strength and tensile strength will increase with increasing strain rate. Elongation values generally decrease as the strain rate increases.

Rebar testing using manually operated machines places a burden on the technician performing the test. The rate of testing is deliberately slow and thus the length of time to test can be long. All the while the operator is expected to be monitoring and adjusting the controls of the machine to ensure there is consistent force application at the specified rate. This is often not the case and inconsistent force application from test to test is the inadvertent result. Undesirable scatter in the test data can occur and sometimes good product gets rejected while at other times out of spec product can be deemed acceptable. Automatic control minimizes this scatter and provides inherent documentation of the testing force application.

| Rebar No. | Diameter (in) | Area(in^2) | 40ksilbf neededto test yield | 60ksilbf neededto test yield | 75ksilbf neededto test yield |

|

3 |

0.375 |

0.11 |

4400 |

6600 |

8250 |

|

4 |

0.500 |

0.20 |

8000 |

12000 |

15000 |

|

5 |

0.625 |

0.31 |

12400 |

18600 |

23250 |

|

6 |

0.750 |

0.44 |

17600 |

22000 |

27500 |

|

7 |

0.875 |

0.60 |

24000 |

36000 |

45000 |

|

8 |

1.000 |

0.79 |

31600 |

47400 |

59250 |

|

9 |

1.128 |

1.00 |

40000 |

60000 |

75000 |

|

10 |

1.270 |

1.27 |

50800 |

76200 |

95250 |

|

11 |

1.410 |

1.56 |

62400 |

93600 |

117000 |

|

14 |

1.693 |

2.25 |

90000 |

135000 |

168750 |

|

18 |

2.257 |

4.00 |

160000 |

240000 |

300000 |

Table 1. Rebar size versus yield strength in pounds force for 3 grades

Note: Not all sizes are available in all strengths. Ultimate tensile strength is typically between 1.33 (larger sizes) to 1.75 (smaller sizes) the yield strength.

Summary of Test

Summary of Test