Compression Testing Universal Testing Systems

ADMET material testing systems are ideal for performing compression tests on a variety of products and materials including concrete, metal, cardboard and plastic packaging, ceramics, and composites. The most common measurement obtained from a compression test is the compressive strength which is the maximum stress a material can withstand before it yields or breaks. It is also possible to measure modulus of elasticity, yield stress, and deformation when performing compression tests. Examples of common tests include measuring the point at which a concrete cylinder breaks under a compressive load, or determining the load at various displacements when compressing a block of polyurethane foam.

Common compression testing definitions and keywords include:

- Compressive strength: The maximum compressive stress a material can withstand before it yields or breaks after gradual compression. Compressive strength measurements are expressed in force per unit area.

- Compressive stress: The compressive load per unit area of minimum original cross section. Compressive strength and compressive stress may or may not be the same values. Compressive stress measurements are expressed in force per unit area.

- Compressive deformation: The decrease in the gauge length area of a test specimen resulting from the applied compressive force. Deformation measurements are expressed in units of length.

- Compressive strain: The ratio of compressive deformation to the gauge length of the test specimen, or the change in length per unit of original length along the y-axis. Strain is a ratio, thus is unit-less.

- Compressive yield point: The first point on a material’s compressive stress-strain curve where an increase in the strain value occurs without an increase in the stress value. Compressive yield strength is the stress at the yield point, expressed as force per unit area.

- Modulus of Elasticity: The ratio of the nominal stress to the corresponding strain below the proportional limit of a material. Modulus measurements are expressed in force per unit area.

- Poisson’s ratio: The ratio of the transverse strain to the axial strain. Poisson’s ratio is a dimensionless ratio.

Common compression testing standards include:

- ASTM C109 – Standard Test Method for Compressive Strength of Hydraulic Cement Mortars

- ASTM D575 – Standard Test Methods for Rubber Properties in Compression

- ASTM D695 – Standard Test Method for Compressive Properties of Rigid Plastics

- ASTM D1621 – Standard Test Method for Compressive Properties Of Rigid Cellular Plastics

- ASTM D2412 – Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

- ASTM D3574 (B1) – Standard Test Methods for Flexible Cellular Materials – Slab, Bonded, and Molded Urethane Foams

- ASTM D3574 (E) – Standard Test Methods for Flexible Cellular Materials – Slab, Bonded, and Molded Urethane Foams

- ASTM D3574 (F) – Standard Test Methods for Flexible Cellular Materials – Slab, Bonded, and Molded Urethane Foams

- ASTM D3574 (X6) – Standard Test Methods for Flexible Cellular Materials – Slab, Bonded, and Molded Urethane Foams

- ASTM D6641 – Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture

- ASTM D7137 – Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates

Compression Testing Equipment

eXpert 2600 Dual Column Testing Machine

The eXpert 2600 series universal testing machines are available in table top or floor standing configurations from 2kN to 600kN.

eXpert 5000 Modular Testing Machine

The eXpert 5000 series testing machines feature configurable frame components and a detachable actuator, giving you the ability to configure your system in a variety of vertical or horizontal orientations.

eXpert 7600 Single Column Testing Machine

The eXpert 7600 series single column testing machines are capable of performing tension, compression, flexure and peel/adhesion tests in an affordable and compact package.

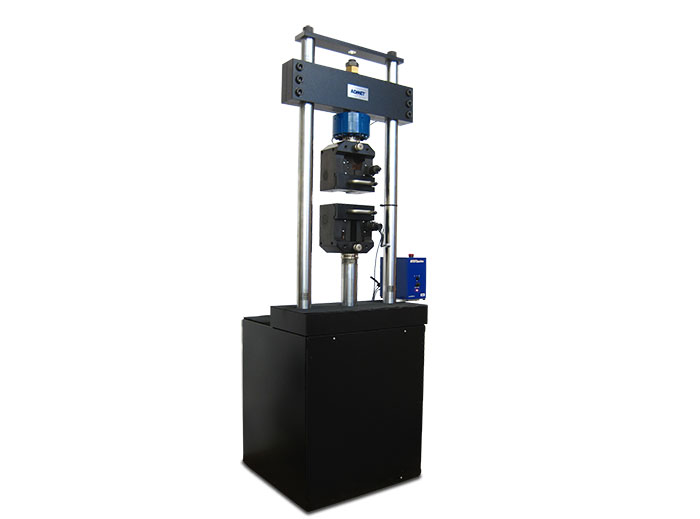

eXpert 1000 Servohydraulic Testing Machine

eXpert 1000 Series servo hydraulic testing machines are ideal for testing metals, composites, medical devices and implants, concrete, webbing, and other materials at very high load capacities without breaking your budget.

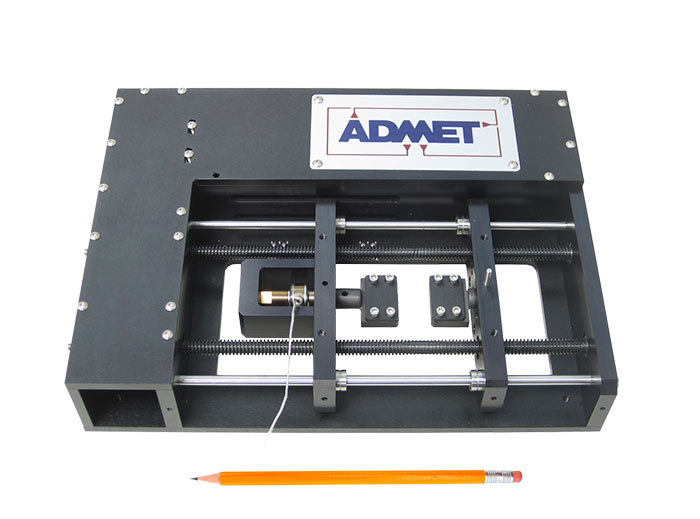

eXpert 4000 Micro Test Machine

The line of eXpert 4000 series MicroTest Systems are ideally suited to meet the demanding requirements for testing miniature samples.

Compression Testing Platens

Compression Platens

Compression platens are used to determine the compression characteristics of materials. ADMET offers circular, square, and spherically seated compression platens as well as multi-purpose t-slot platens. Platens are commonly manufactured from aluminum or steel and attach to the testing machine with an eye-end connector appropriate for the load capacity. We also offer compression fixture packages for ASTM C469 and ASTM D695 testing.

Compression Testing Image Gallery

- Plastic pipe compression testing per ASTM D2412

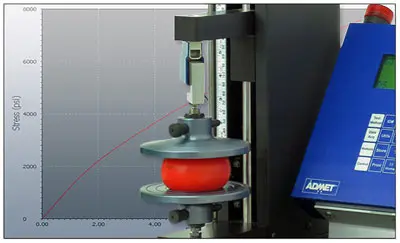

- Foam compression testing on an eXpert 5600F

- Specialized Compression Fixture and Transducer for ASTM D695

- Compression testing on an eXpert 7600