ASTM D1894 is a testing standard designed to measure the friction of plastic film and sheeting. This post should help you understand the basics of the test procedure and help you choose the right equipment to perform this test accurately. For complete instructions and before testing your products to ASTM D1894, please refer to the official specification.

Procedure:

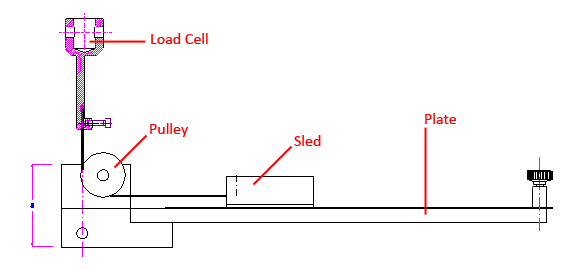

- This test requires the use of a special fixture consisting of two main parts: a sliding plane or plate, and a sled. This test can be performed on a material sliding over itself or on another type of surface.

- Cut the material to be tested to the specified size.

- Tape the material to the plate (make sure there are no wrinkles).

- Cut and tape the material or special surface to the sled using the specified method.

- Run the string attached to the sled through the pulley and connect it to the load cell on the testing machine actuator.

- Begin pulling the string at the specified rate.

- Record the load when the specimen begins to move.

- Continue pulling the sled making sure the data is being graphically recorded.

- Stop the test once the specified sliding distance has been covered.

Analysis:

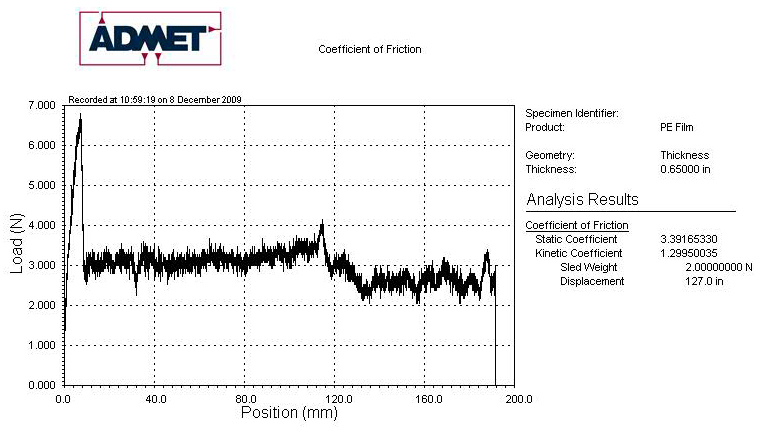

- Static coefficient of friction (initial load)

- Kinetic coefficient of friction (average load during smooth travel)

Equipment Recommended:

- A specialized fixture with a sled, plate, and pulley that satisfy the requirements indicated in the

specification. ADMET offers a full line of grips and fixtures for coefficient of friction testing. We are happy to custom design a fixture to meet special requirements. - A testing machine capable of pulling the sled at the specified rate equipped with a load cell capable of recording load at the required sensitivity.The eXpert series of electromechanical testing machines (available in single and dual column configurations) are perfect of this type of application. Load capacity and physical space requirements should determine which system is best for your application.

- A testing controller capable of moving the machine actuator at a constant rate, indicate and record load, and display a graph of the test data.MTESTQuattro®, our most advanced testing controller, is a PC-based unit that offers a wide range of flexibility in control, data acquisition, analysis, and reporting. The eP2 Digital Controller, a standalone touch panel unit, offers a balance between performance and simplicity. Both controllers satisfy these requirements.