Straight out of a fairytale, the materials manufacturing sectors may have the ability to develop self-healing devices in the near future. According to a CNN article, anti-corrosion coatings have already been created, which may improve safety and increase the lifespan of certain materials.

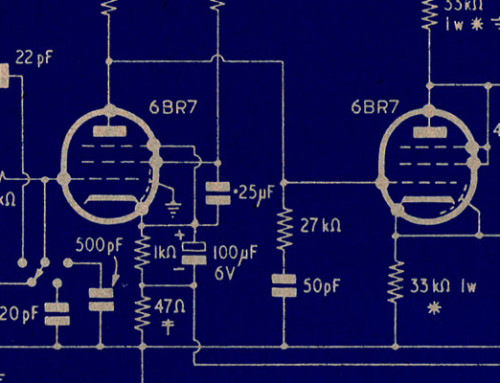

The technology company Autonomic Materials has taken part in inventing self-restructuring sealants, adhesives and coatings, which use electrical circuits to fix any cracks or breaks in the material. Applications for this breakthrough coating include ships, docks or oil and gas platforms.

The major benefits of these self-healing devices are geared toward decreasing corrosion of metals and reducing the maintenance periods while expanding the lifetime of the materials. With corrosion and maintenance costing $500 billion annually across the globe, it is greatly advantageous to incorporate these types of adhesives during construction. The way this coating works is by incorporating two microcapsules, one with a self-healing portion while the other acts as a catalyst upon damage.

At the UK-based University of Bristol, Professor Ian Bond developed a vascular system in which hollow fibers would hold liquids that would seep out and repair damage upon impact. This is meant to be used on aircraft carriers. However, this may not be an all-encompassing solution, as “the cracks will disappear but you wouldn’t restore the structural integrity,” Bond told the news source.

ScienceDaily reported on the use of self-healing coating for protecting concrete and other building materials. Decreasing the number of cracks and breaks in bridges and roads is vital to the overall safety of such structures, as water and salt that seeps into these cracks lead to the decay of concrete materials.

A study published in the ACS Applied Materials & Interfaces journal explains that the coating works when sunlight activates the sealant and solidifies the glue that repairs the cracks in the concrete.

“Our self-healing coating is the first example of capsule-type photo-induced self-healing system, and offers the advantages of catalyst-free, environment-friendly, inexpensive, practical healing,” the authors of the study stated in their report.

Engineers, scientists and manufacturers servicing the adhesives market will likely see a rise in demand for these types of sealants and coatings. However, before offering any new or traditional products for sale, it is imperative to test the effectiveness of the sealants and coatings on maintaining or enhancing the strength of the underlying materials after repair.

Testing these New Coatings

Breakthroughs like this are clearly exciting but rigorous testing is symbiotic to this environment. ADMET offers a wide range of ASTM and ISO compliant testing systems for measuring the performance and strength of the sealants, coatings and underlying materials in a variety of conditions. The eXpert 5000 Series and eXpert 7600 Series testing machines are well suited for performing adhesive tests on the sealants and coatings. The modular design of the eXpert 5000 Series machines also allow one to test up to three samples at a time.

The eXpert 2600 Series Dual Column Testing Machines are a good choice for testing the strength of metals prior to and after the application of the sealants and coatings. ADMET eXpert 5000 and 3930 Series Fatigue Testing Machines can be employed to initiate cracks in the underlying materials to simulate damage. After the sealants and coatings have been applied, the fatigue testing systems can then be used to measure the resulting toughness of the material. ADMET also offers heating and cooling chambers and fluid baths to simulate the real-world conditions these materials reside in.

To accommodate concrete and construction developers, ADMET offers our MegaForce Automatically Controlled Compression Testing Machines for determining the strength of the repaired concrete according to ASTM C39, C78 and C469 testing standards. The MegaForce control system can be purchased either with a new machine or retrofitted to an existing older version.

Any manufacturers – whether developing solutions in the adhesives, concrete, medical devices or automobile sectors – can work with the staff at ADMET to develop solutions to their materials testing needs. Whether an investment in a new system or a retrofit to your existing system makes sense, the sales team at ADMET can provide the answers you are seeking.