澳洲幸运10正规彩票-幸运澳洲十官网-澳洲10查询开奖记录-澳洲幸运10开奖结果-ADMET Testing Systems

Material Testing System Manufacturer

澳洲幸运10官网开奖记录查询, 澳洲幸运10官网开奖结果历史记录查询 澳洲幸运10历史开奖官网开奖结果直播计划-ADMET Testing Systems

Material Testing System Manufacturer

澳洲幸运10历史开奖查询 168澳洲幸运十正规官网 幸运澳洲十开奖直播 澳洲幸运10开奖官网开奖记录 澳洲幸运10开奖历史记录 ADMET Testing Systems

Material Testing System Manufacturer

ADMET Has Helped Businesses Around the World

Solve Their Materials Testing Challenges

How can we help you today?

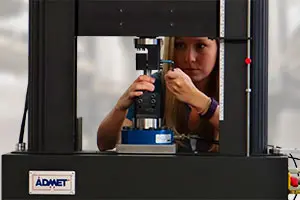

At ADMET, Customers Come First

Our approach is always the same: get to know the customer, diagnose their issues and assess whether we can improve their performance. We can’t always help. However, after over 30 years of solving materials testing problems across a wide spectrum of industries, we have built the enviable reputation of making customers happy.

eXpert 7600 Single Column

The eXpert 7600 series single column universal testing systems are capable of performing tension, compression, flexure and peel/adhesion tests in an affordable and compact package. Efficient in design with force capacities to 5 kN, the eXpert 7600 series machines feature the industry’s largest vertical test space, making them ideal for testing high elongation materials.

- Capacity up to 5 kN (1,000 lbf); Speeds up to 2,540 mm/min (100 in/min)

- Efficiently designed unit fits into 431×520 mm (17×20.5 in) footprint

- Exceeds ASTM and ISO accuracy standards

- Read the eXpert 7600 brochure

168澳洲幸运10官网历史结果查询 澳洲幸运10开奖记录历史查询 2025澳洲幸运10+168澳洲幸运十开奖体彩官网|正规澳洲结果查询 eXpert 2600 Dual Column

The eXpert 2600 series universal testing systems are available in table top or floor standing configurations from 2 kN to 300 kN. The 2600 series testers tackle the toughest tests with their superior axial alignment, stiffness, and crosshead guidance. A simple yet customizable design allows for lower cost, faster delivery, and years of maintenance free operation.

- Capacity up to 300 kN (67,500 lbf); Speeds up to 2,540 mm/min (100 in/min)

- Table top units available in horizontal or vertical configuration

- Exceeds ASTM and ISO accuracy standards

- Read the eXpert 2600 brochure

eXpert 1000 Servohydraulic

The eXpert 1000 series servohydraulic universal testing systems are ideal for testing metals, composites, medical devices and implants, concrete, webbing, and other materials at very high load capacities without breaking your budget. Each frame employs strain gauge load cells for direct measurement of force. These frames offer exceptional accuracy and precision in a simple low maintenance design.

- Capacity up to 600 kN (135,000 lbf); Speeds up to 482 mm/min (19 in/min)

- No need to compensate for piston friction and other non-linearities

- Exceeds ASTM and ISO accuracy standards

- Read the eXpert 1000 Brochure

Biaxial Testing Systems

Ideal for simulating real-world conditions, ADMET offers both planar biaxial and axial-torsion test systems. Both types of systems can be offered with fatigue or static actuators. ADMET’s axial-torsion test systems are offered by adding a torsion actuator to one of our standard single or dual-column testing frames; providing you the flexibility to perform axial-torsion, uniaxial, and torsion-only tests with one machine.

- Static axial capacity up to 50 kN (10,000 lbf);

- Speed tailored to testing requirements

- Torque capacity up to 100 Nm (884 in-lbf)

- Exceeds ASTM and ISO accuracy standards

- Read the eXpert 8600 brochure

eXpert 5000 Modular

The eXpert 5000 series universal testing systems feature configurable frame components and a detachable actuator. This modular design approach gives the operator the ability to arrange their system in a variety of vertical or horizontal orientations. Perfect for users wanting to perform a variety of tests on a single machine, the 5000 is ADMET’s most affordable testing system.

- Capacity up to 10 kN (2,250 lbf); Speeds up to 15,240 mm/min (600 in/min)

- ASTM-specific configurations for foam, adhesive, and friction testing available

- Exceeds ASTM and ISO accuracy standards

- Read the eXpert 5000 brochure

168澳洲10官网开奖 开奖体彩结果查询 现场直播 澳洲10开奖历史记录查询 168澳洲幸运10官方开奖结果历史 -澳洲体彩幸运10开奖记录 eXpert 4000 Micro Tester

The eXpert 4000 is a full featured miniature testing machine that performs tension, compression and bend tests at capacities up to 5 kN (1,125 lb). The eXpert 4000 features opposing moving crossheads which means the center of the specimen never moves; a necessary feature when the eXpert 4000 is used with a microscope for measuring the strain properties of materials.

- Capacity up to 5 kN (1,000 lbf); Speeds up to 500 mm/min (20 in/min)

- Adaptable to microscope stages and capable of milligram low force testing

- Exceeds ASTM and ISO accuracy standards

- Read the eXpert 4000 brochure

Torsion Testing Systems

ADMET eXpert 9000 torsion testers employ a linear slide design for maximum torsional stiffness and minimal axial friction. A reaction torque transducer is attached to a movable tail stock mounted on a linear slide. The tail stock can be left free floating or clamped during testing. All torsion testers feature unlimited rotation in both directions and are ordered as either horizontal or vertical testers.

- Torque capacity up to 300 Nm (2,650 in-lbf); Speeds up to 40 RPM

- Available in vertical or horizontal orientations

- Exceeds ASTM and ISO accuracy standards

- Read the eXpert 9000 brochure

Fatigue Testing Systems

The eXpert 5900 series tabletop dynamic testing machine is a compact, quiet, and clean electro-dynamic testing system. ADMET also offers the eXpert 9900 torsion fatigue tester and eXpert 1900 servohydraulic fatigue tester for high-force applications. Fatigue testing systems are equipped with either the MTESTQuattro or DC1x high-speed closed-loop controllers.

- Capacity up to 250 kN (56,000 lbf); Speeds up to 20,320 mm/min (800 in/min)

- Electromechanical or servo hydraulic

- Exceed ASTM and ISO accuracy standards

- Read the fatigue tester overview brochure

BioTense Bioreactor

The BioTense Perfusion Bioreactor is an innovative instrument to help tissue engineers and cell biologists perform high resolution investigation in mechanobiology. Unique to the BioTense is its ability to apply mechanical stimulation and directly observe cell/matrix interaction at magnification over long periods of time. The Bioreactor sits atop the XYZ stage of an inverted microscope.

- Maintains desired concentrations of nutrients through a perfusion process

- Provides a window to directly observe cellular activity at high magnification

- Accurately controls reactor temperature

- Read the BioTense Bioreactor brochure

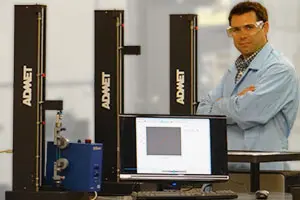

What can an ADMET Universal Testing System retrofit do for you?

By pairing an older system with an ADMET controller or indicator, the functionality of the system is transformed. An ADMET retrofit will increase the accuracy and capability of your testing system and ensure that your tests are consistently and reliably performed to defined testing standards. With a modern computerized system, your results are calculated quickly and error free and are easily exported into a wide variety of report formats.

ADMET retrofits electromechanical and servohydraulic testing machines from ATS, Baldwin, Instron, MTS, Riehle, SATEC, Shimadzu, Tinius Olsen, United, and more! In addition to adding controllers and indicators, ADMET can upgrade a system with a new servo motor, servohydraulic power unit, actuator, load cell, or pressure transducer as well as convert the system to full closed-loop automatic control. Talk to one of our experienced staff about retrofitting your machine today!

Read Our Case Studies and See What ADMET Customers Have to Say

For over 30 years, ADMET has been helping companies solve their material testing challenges.

Here are some stories of how we’ve worked with our customers to improve their testing process.

Aerospace

A major corporate jet manufacturer was asked by its customers to expand its maintenance and testing capabilities. They needed a universal testing system that could accommodate components from a broad range of aircraft from many manufacturers. Where could they find a universal testing machine that could be designed to meet all their needs and their budget?

Automotive

Dexter Axle performs routine tests of daily in-process manufacturing friction welds on axle assemblies using a Reihle electromechanical tensile testing machine. However, Dexter’s main line of heavy duty axles, Torflex, uses rubber components that are integral to the product’s performance. The question: how do you test these rubber components?

Medical Devices

Karl Storz is an international manufacturer of medical devices and instruments. In order to develop better, stronger products, engineers needed to gain more structural and performance information about their endoscope tubing. They considered building their own universal testing system, but this proved unrealistic. What did they do next?

Why do Customers Choose 幸运澳洲10官网 澳洲幸运10官网开奖结果历史 澳洲幸运10开奖视频直播结果 澳洲幸运10正规官网开奖 澳洲幸运10开奖官网开奖|幸运澳洲10开奖结果数据+历史开奖记录 ADMET?

Learn about our core values or determine if investing in universal testing equipment makes sense for your company.