Mechanical Testing Solutions for Concrete

Concrete has been in use for construction for over 2,000 years, but modern technology has had a major impact on even a simple material like concrete. In addition to steel reinforcing bar, advanced fibers are used to strengthen concrete in structural applications as well as high-temperature/high-pressure applications in oil and gas drilling. Changes in the material parameters need to be carefully measured during product development as well as monitoring samples taken during construction. The test methods are clearly specified according to the ASTM specs listed below. ADMET has been involved with concrete testing for many years, from retrofitting simple compression test frames with servo control to providing advanced high-temperature systems to measure the Modulus of Elasticity and Poisson’s Ratio at operating temperatures. Analysis routines are built into the software for ease of use and fast time-to-results.

Common testing standards for concrete include:

- ASTM C39 – Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens

- ASTM C78 – Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading)

- ASTM C109 – Standard Test Method for Compressive Strength of Hydraulic Cement Mortars

- ASTM C469 – Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression

- ASTM C1609 – Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading)

- ASTM D5801- Standard Test Method for Toughness and Tenacity of Asphalt Materials

- EN 14651 – Concrete Flexural Tensile Testing

- eXpert 2657 (300 kN) – With ASTM C1609 fixturing and optional computer

- ASTM C1609 Fixture with Displacement Transducer

- eXpert 2654 equipped for EN 14651 cement testing with CMOD transducer

- Concrete compression testing per ASTM C469

- Double Punch Concrete Test Fixture

- ADMET MegaForce performing ASTM C78 concrete beam bend testing

- ASTM C469 Test Setup

Externally hosted articles:

- Automating Cylinder Strength Test Reports (Concrete Producer)

- Crossing the Digital Divide – Automated concrete testing at the Biloxi Bay Bridge (The Construction Specifier)

ADMET Articles:

| Concrete | Recommended Equipment |

|---|---|

| Testing System / Fixture | |

| Indicators & Software |

|

| Other |

|

Concrete Testing Products

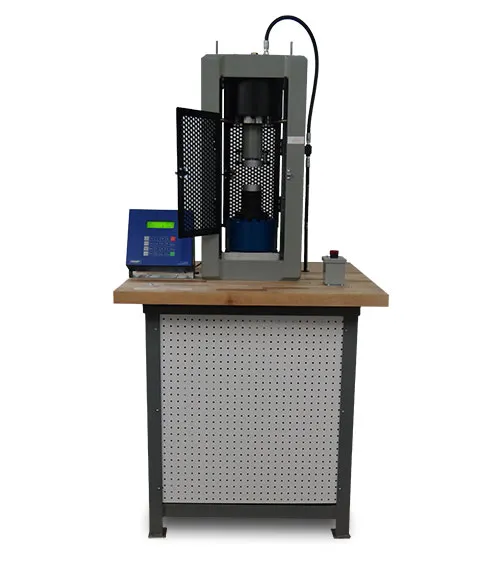

DFG

Concrete Indicator

ADMET’s DFG Concrete Indicator is the ideal instrument for conducting consistent and accurate testing on concrete cylinders and beams and cement cubes in accordance with AASHTO and ASTM standards. The indicator’s simple, easy-to-use interface increases efficiency and minimizes user error.

Compressometer

Assembly

ADMET’s assembly includes a compressometer and transducers in axial and/or transverse directions. It is used to evaluate the deformation and strain characteristics such as Poisson’s ratio and Young’s Modulus which can be calculated with the GaugeBuster 2 indicator and GaugeSafe Plus or Live.